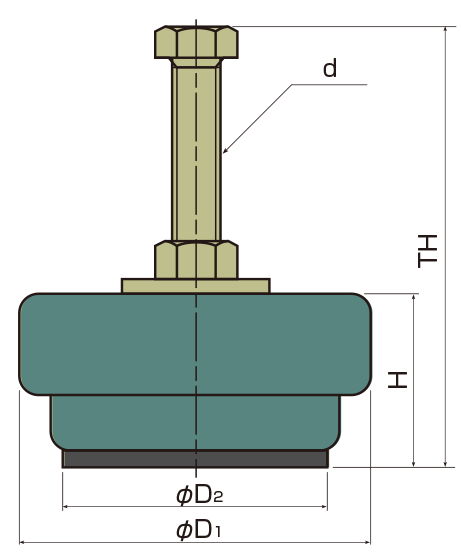

| Part number | Minimum load N. | Maximum load N. | φD1 | φD2 | (H) | (H) Level adjustment amount | d | bolt length L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

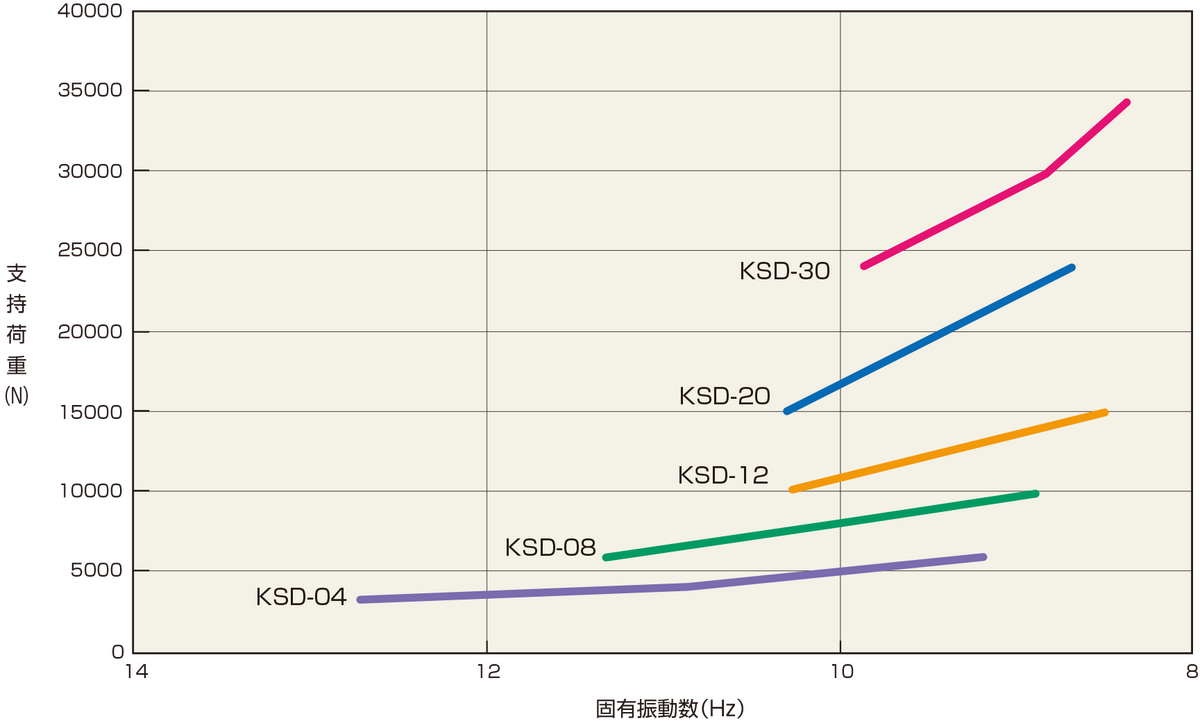

| KSD-04 | 2900 | 5900 | 150 | 112 | 65 | +15 | M20 | 120 | 180 | 59 |

| KSD-08 | 5900 | 9800 | 150 | 112 | 65 | +15 | M20 | 120 | 180 | 59 |

| KSD-12 | 9800 | 14700 | 150 | 112 | 66 | +10 | M20 | 120 | 180 | 64 |

| KSD-20 | 14700 | 23500 | 150 | 112 | 73 | +10 | M20 | 120 | 190 | 64 |

| KSD-30 | 23500 | 33300 | 150 | 112 | 78 | +7 | M20 | 120 | 195 | 67 |

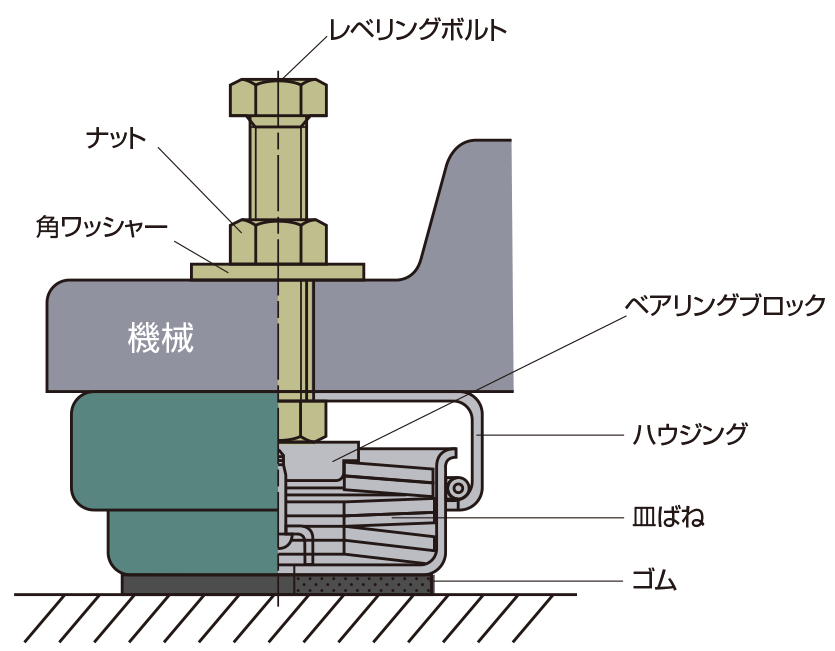

*If the mounting hole of the machine is φ35 or larger, insert a thick square washer of □50 or larger between the machine and the KSD housing.

1. Place the spring high mount under the bolt hole of the machine to be damped.

2. Insert the bolt into the threaded hole of the spring high mount from the top and screw it into the bearing block until it stops.

3. The level can be adjusted by screwing in the leveling bolt to increase the height of the spring high mount.

4. Then fully tighten the nut.

*Floor discoloration may be seen on the resin base floor etc. due to the spring high mount installation.

Especially if you want to avoid it, please refrain from using it.

Machine press (small/medium size), shirring, bender, etc.

Milling machine, shaping machine, broaching machine, slotter, etc.

Injection molding machines, rolls, crushers, printing machines, food processing machines, wire processing machines, etc.

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry