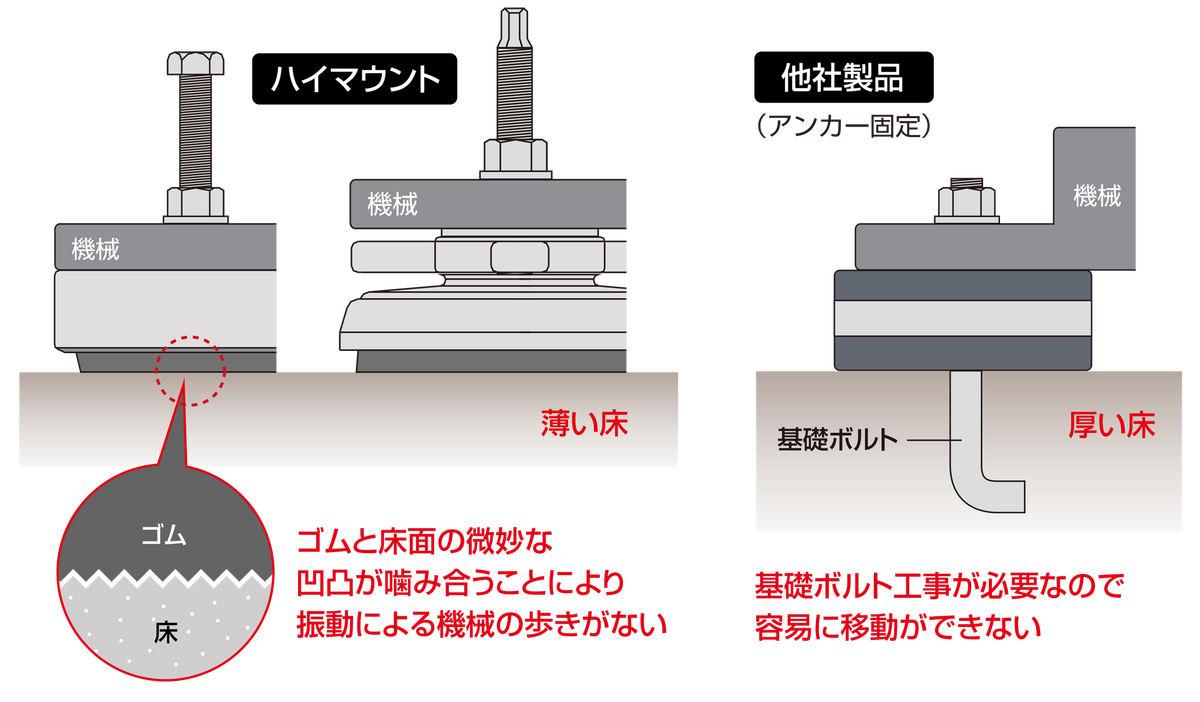

・Excellent anti-vibration performance

・Uses special rubber that does not stain the floor (according to our test method)

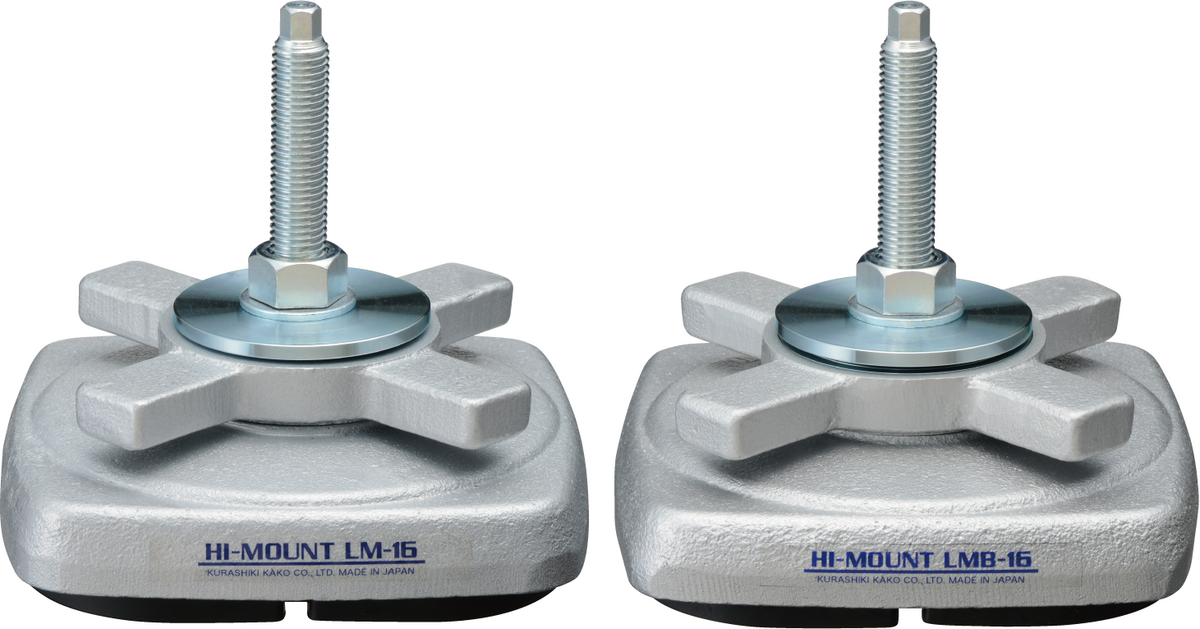

・Uses special rubber with excellent durability against oil and ozone (LM/LMB series)

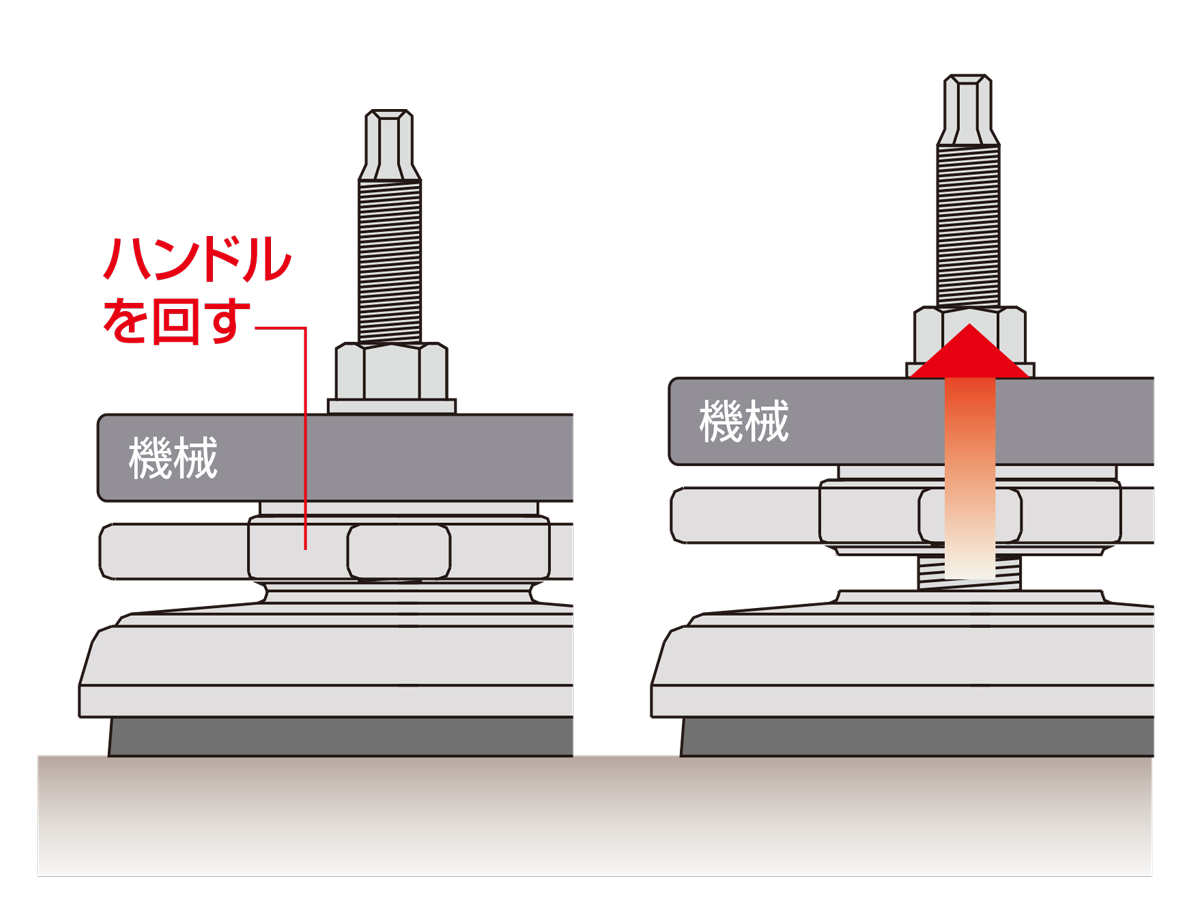

・Built-in bearings in the handle allow for smoother leveling (LMB series)

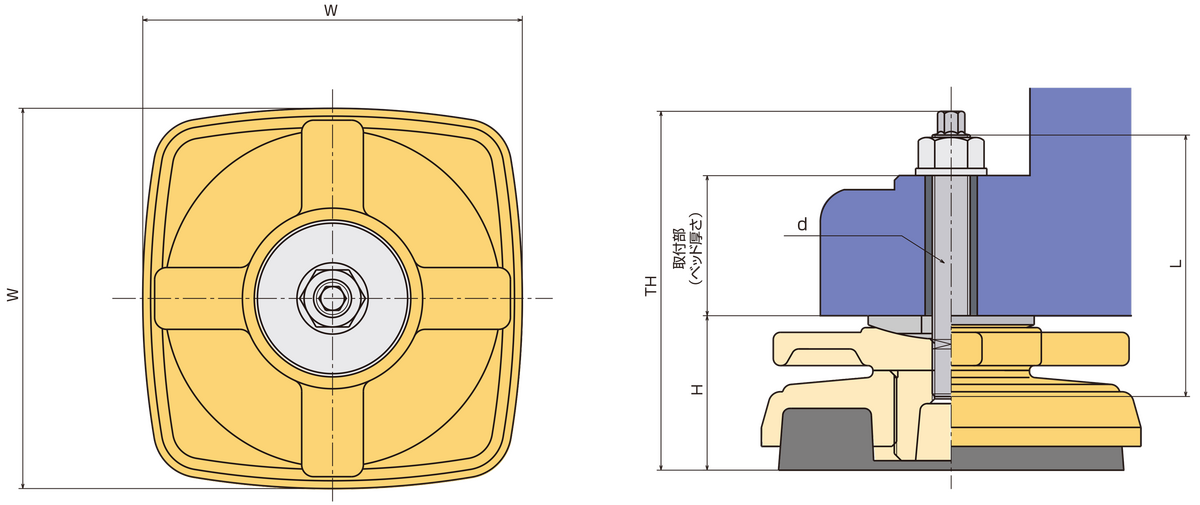

・Significant damping effect by adopting high damping rubber (LMY series)

・The machine does not walk due to vibration, and the layout can be changed according to the environment.

・Natural frequency: 18-26Hz

・Load range: 1400 to 18000N

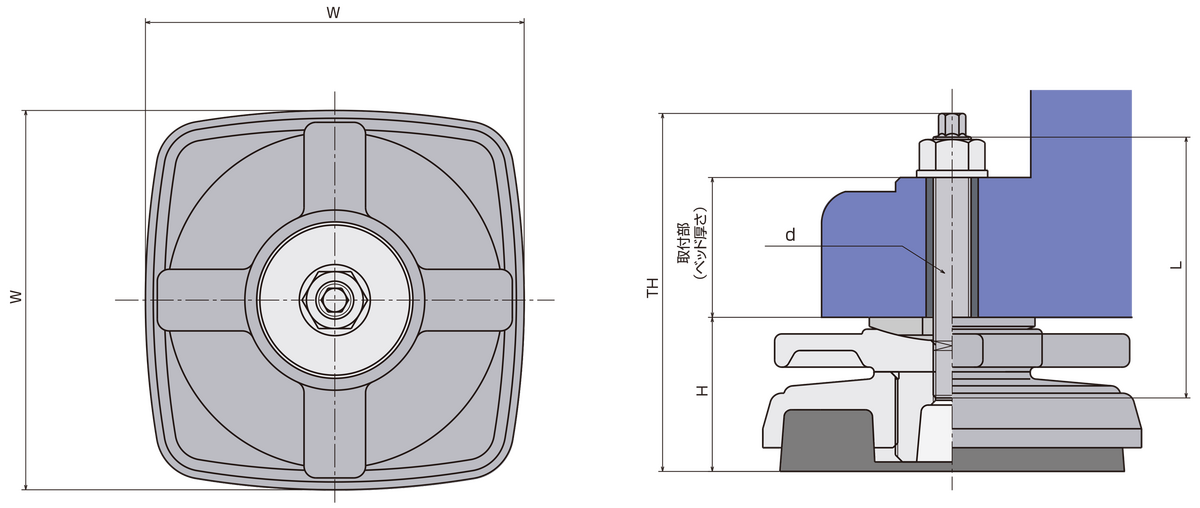

・Handle bearing mechanism (LMB series only)

・Natural frequency: 18-26Hz

・Load range: 1400 to 18000N

・Adoption of high damping rubber

・Anti-vibration rubber: Chloroprene rubber

・Level washer: Unichrome plating

・Housing: Spark silver metallic (melamine baked finish)

・Bolts: Unichrome plating

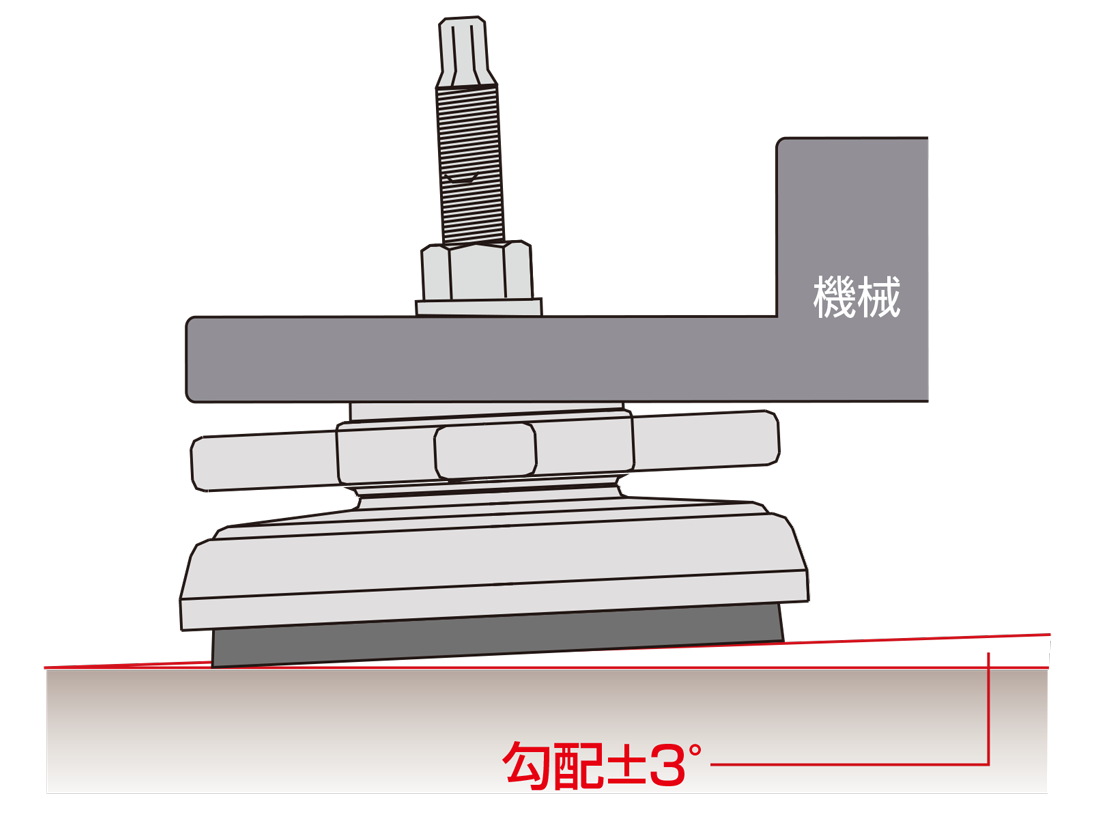

*LM(B)-16 and LM(B)-20 cannot be leveled up when installed at an angle.

Please use it for fine adjustment after jacking up.

| Part number | Minimum load N. | Maximum load N. | spring constant N/mm | W. | (H) | (H) Level adjustment amount | d | L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

| LM-11 | 1400 | 2800 | 3700 | 110 | 47 | +15 | M12 | 85 | 115 | ~ 45 |

| LM-11-200L | 1400 | 2800 | 3700 | 110 | 47 | +15 | M12 | 200 | 230 | ~ 160 |

| LM-13 | 2800 | 6000 | 7400 | 130 | 48 | +20 | M16 | 110 | 138 | ~ 60 |

| LM-13-200L | 2800 | 6000 | 7400 | 130 | 48 | +20 | M16 | 200 | 228 | ~ 150 |

| LM-16 | 6000 | 12000 | 14700 | 160 | 62 | +24 | M16 | 110 | 148 | ~ 55 |

| LM-16-200L | 6000 | 12000 | 14700 | 160 | 62 | +24 | M16 | 200 | 238 | ~ 145 |

| LM-20 | 12000 | 18000 | 23000 | 200 | 72 | +27 | M20 | 130 | 173 | ~ 65 |

| LM-20-220L | 12000 | 18000 | 23000 | 200 | 72 | +27 | M20 | 220 | 263 | ~ 155 |

| LMB-16 | 6000 | 12000 | 14700 | 160 | 62 | +24 | M16 | 110 | 148 | ~ 55 |

| LMB-20 | 12000 | 18000 | 23000 | 200 | 72 | +27 | M20 | 130 | 173 | ~ 65 |

・Anti-vibration rubber: High damping rubber

・Level washer: Unichrome plating

・Housing: Yellow (melamine baking finish)

・Bolts: Unichrome plating

* LMY-16 and LMY-20 cannot be leveled up when installed at an angle.

Please use it for fine adjustment after jacking up.

| Part number | Minimum load N. | Maximum load N. | spring constant N/mm | W. | (H) | (H) Level adjustment amount | d | L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

| LMY-11 | 1400 | 2800 | 3700 | 110 | 47 | +15 | M12 | 85 | 115 | ~ 45 |

| LMY-11-200L | 1400 | 2800 | 3700 | 110 | 47 | +15 | M12 | 200 | 230 | ~ 160 |

| LMY-13 | 2800 | 6000 | 7400 | 130 | 48 | +20 | M16 | 110 | 138 | ~ 60 |

| LMY-13-200L | 2800 | 6000 | 7400 | 130 | 48 | +20 | M16 | 200 | 228 | ~ 150 |

| LMY-16 | 6000 | 12000 | 14700 | 160 | 62 | +24 | M16 | 110 | 148 | ~ 55 |

| LMY-16-200L | 6000 | 12000 | 14700 | 160 | 62 | +24 | M16 | 200 | 238 | ~ 145 |

| LMY-20 | 12000 | 18000 | 23000 | 200 | 72 | +27 | M20 | 130 | 173 | ~ 65 |

| LMY-20-220L | 12000 | 18000 | 23000 | 200 | 72 | +27 | M20 | 220 | 263 | ~ 155 |

*Apply the natural frequency when the excitation force of the machine is generated in the vertical direction.

*If stability is important, the support load should be less, and if vibration isolation is important, apply more within the maximum load range.

*If vibration isolation performance is important, select a model that matches the supporting load at each point and make the natural frequencies as uniform as possible.

*Please use the M series B type to reduce impact force such as sheet metal press.

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry