・Excellent anti-vibration performance

・Uses special rubber that does not stain the floor (according to our test method)

・Uses special rubber that is resistant to oil and ozone and has excellent durability (M series)

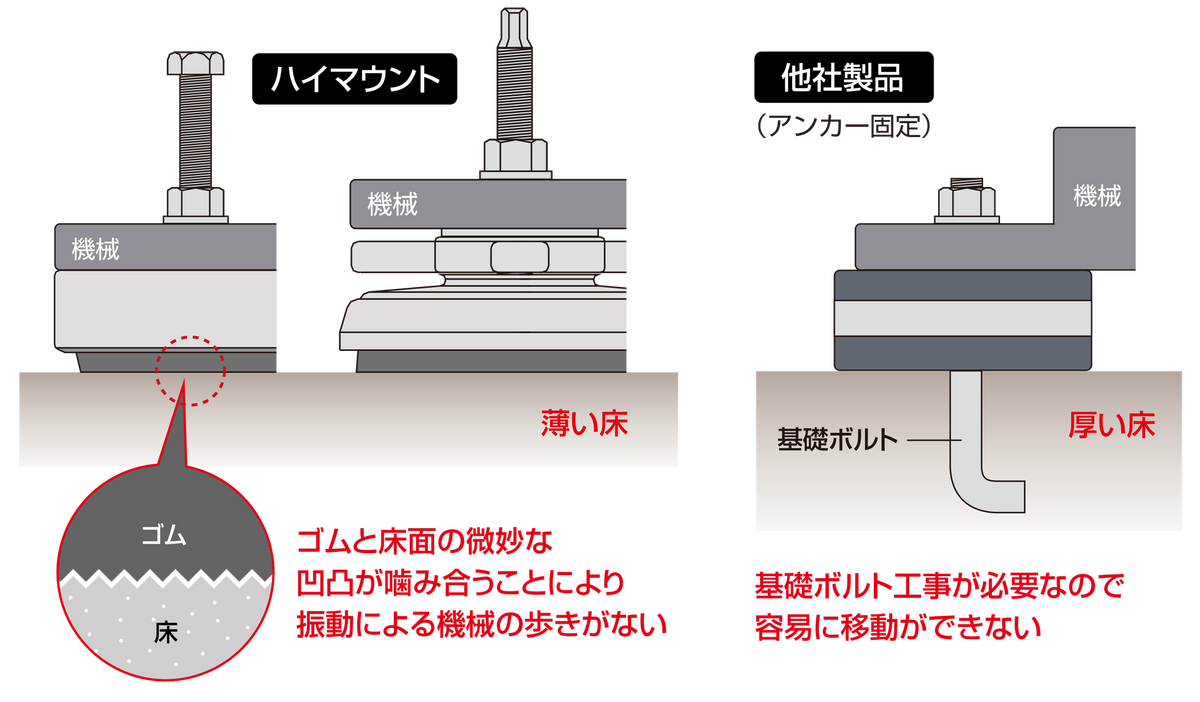

・The machine does not walk due to vibration, and the layout can be changed according to the environment.

・Natural frequency: 10-28Hz

・Load range: 1550 to 40000N

・Natural frequency: 14-28Hz

・Load range: 3150 to 40000N

・Adoption of high damping rubber

・Anti-vibration rubber: Chloroprene rubber

・Housing: Spark silver metallic (melamine baked finish)

・Bolts: Unichrome plating

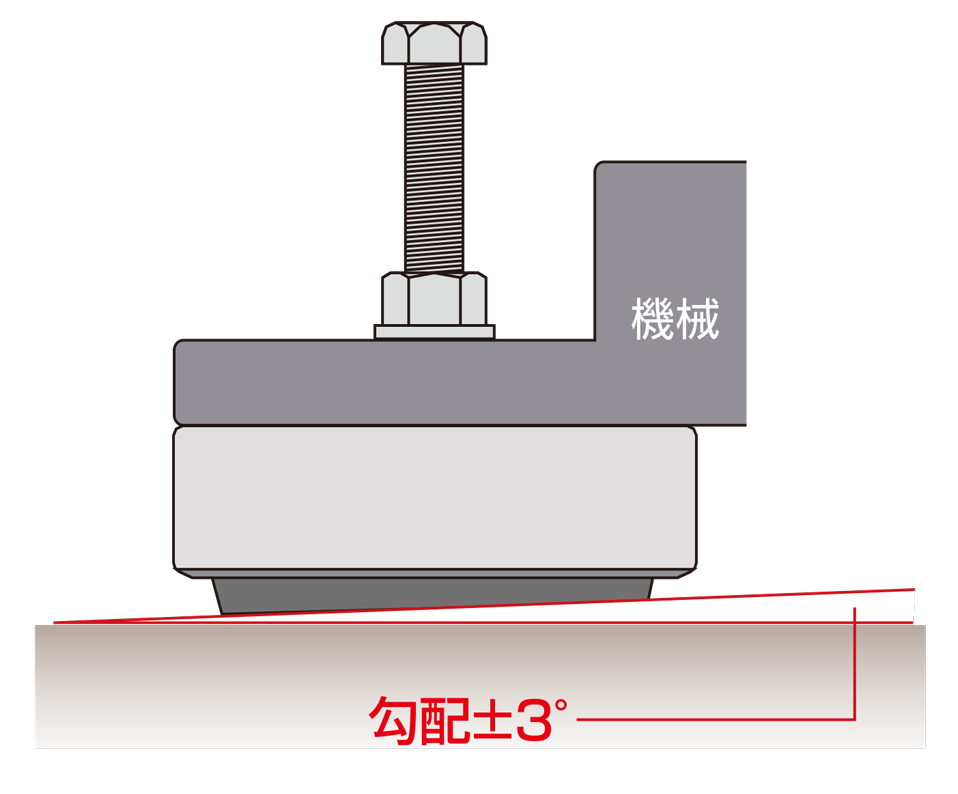

*When installing on an inclined surface (permissible gradient: 3° or less), please level at 50% or less of the maximum adjustment amount.

(M-19* cannot be leveled up when it is installed at an angle. Please use it for fine adjustment after jacking up.)

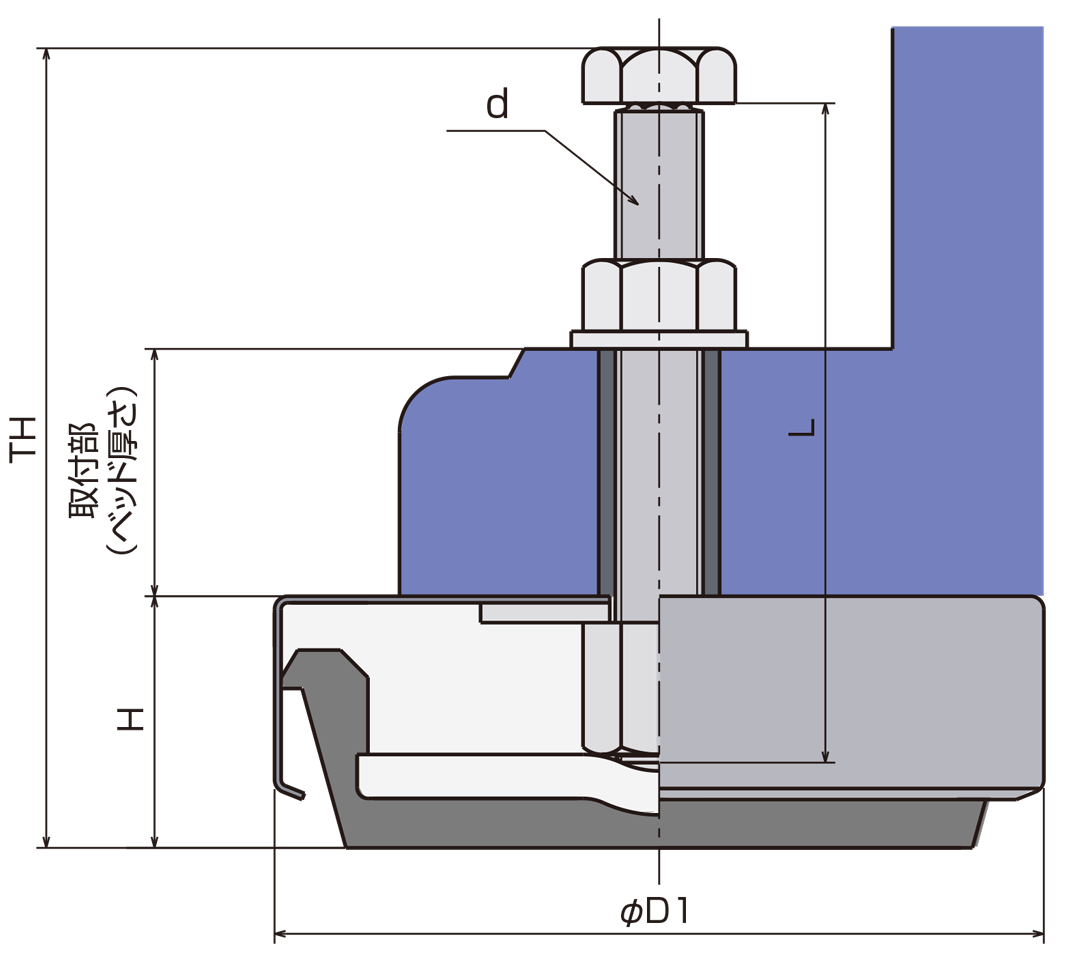

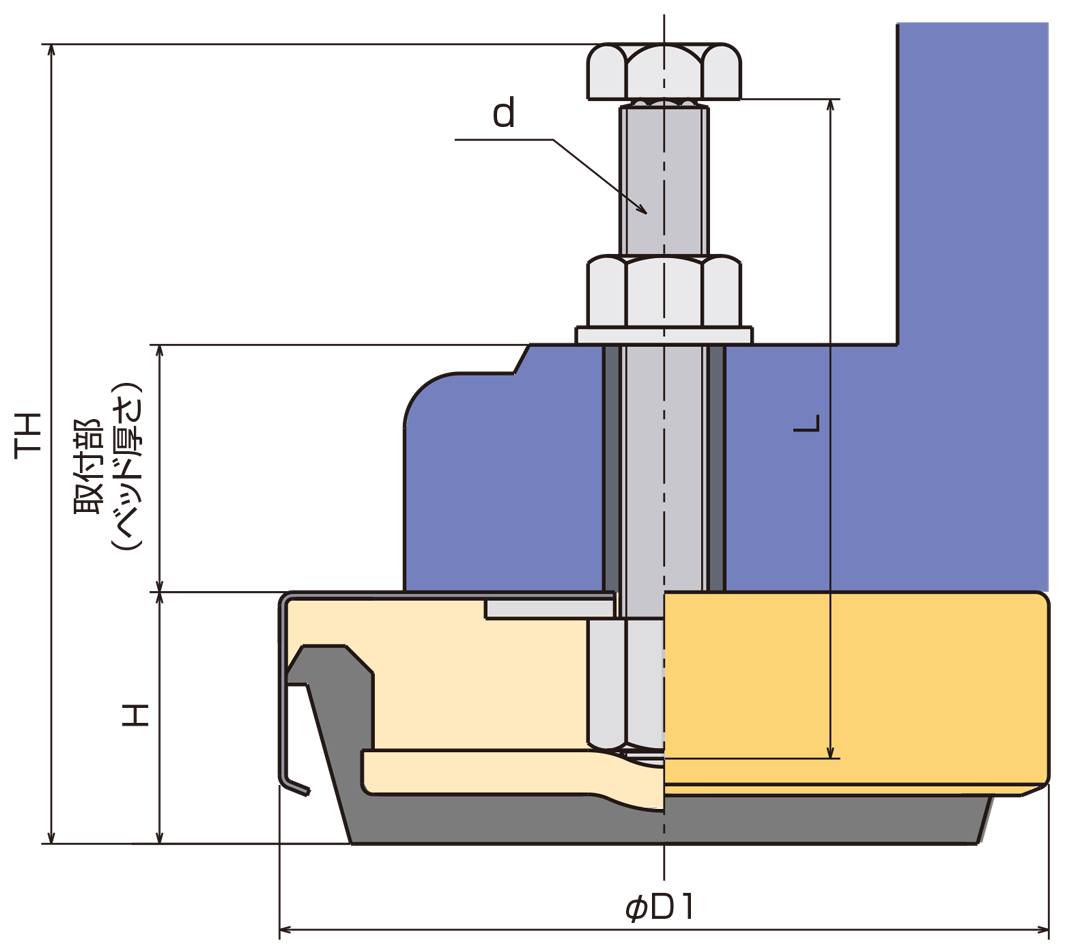

| Part number | Minimum load N. | Maximum load N. | spring constant N/mm | φD1 | (H) | (H) Level adjustment amount | d | L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

| M-10A | 1550 | 3100 | 1200 | 100 | 39 | +18 | M12 | 90 | 121 | ~ 42 |

| M-10A-120L | 1550 | 3100 | 1200 | 100 | 39 | +18 | M12 | 120 | 151 | ~ 72 |

| M-10A-200L | 1550 | 3100 | 1200 | 100 | 39 | +18 | M12 | 200 | 231 | ~ 152 |

| M-14A-90L | 3100 | 6300 | 2400 | 140 | 47 | +19 | M16 | 90 | 127 | ~ 35 |

| M-14A | 3100 | 6300 | 2400 | 140 | 47 | +19 | M16 | 120 | 157 | ~ 65 |

| M-14A-200L | 3100 | 6300 | 2400 | 140 | 47 | +19 | M16 | 200 | 237 | ~ 145 |

| M-19A | 6300 | 12500 | 4800 | 190 | 56 | +25 | M20 | 120 | 164 | ~ 51 |

| M-19A-200L | 6300 | 12500 | 4800 | 190 | 56 | +25 | M20 | 200 | 244 | ~ 131 |

The external dimensions of types A and B are the same.

| Part number | Minimum load N. | Maximum load N. | spring constant N/mm | φD1 | (H) | (H) Level adjustment amount | d | L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

| M-10B | 3150 | 6300 | 4600 | 100 | 39 | +18 | M12 | 90 | 118 | ~ 39 |

| M-10B-120L | 3150 | 6300 | 4600 | 100 | 39 | +18 | M12 | 120 | 148 | ~ 69 |

| M-10B-200L | 3150 | 6300 | 4600 | 100 | 39 | +18 | M12 | 200 | 228 | ~ 149 |

| M-14B-90L | 6300 | 12500 | 9200 | 140 | 47 | +19 | M16 | 90 | 127 | ~ 35 |

| M-14B | 6300 | 12500 | 9200 | 140 | 47 | +19 | M16 | 120 | 157 | ~ 65 |

| M-14B-200L | 6300 | 12500 | 9200 | 140 | 47 | +19 | M16 | 200 | 237 | ~ 145 |

| M-19B | 12500 | 25000 | 18300 | 190 | 56 | +25 | M20 | 120 | 164 | ~ 51 |

| M-19B-200L | 12500 | 25000 | 18300 | 190 | 56 | +25 | M20 | 200 | 244 | ~ 131 |

The external dimensions of types A and B are the same.

| Part number | Minimum load N. | Maximum load N. | spring constant N/mm | φD1 | (H) | (H) Level adjustment amount | d | L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

| M-10H-90L | 7500 | 15000 | 23000 | 100 | 35 | +22 | M12 | 90 | 107 | ~ 28 |

| M-10H | 7500 | 15000 | 23000 | 100 | 35 | +22 | M12 | 120 | 137 | ~ 58 |

| M-10H-200L | 7500 | 15000 | 23000 | 100 | 35 | +22 | M12 | 200 | 217 | ~ 138 |

| M-14H-90L | 15000 | 30000 | 46000 | 140 | 42 | +24 | M16 | 90 | 111 | ~ 19 |

| M-14H | 15000 | 30000 | 46000 | 140 | 42 | +24 | M16 | 120 | 141 | ~ 49 |

| M-14H-200L | 15000 | 30000 | 46000 | 140 | 42 | +24 | M16 | 200 | 221 | ~ 129 |

| M-19H | 20000 | 40000 | 62000 | 190 | 54 | +27 | M20 | 120 | 148 | ~ 36 |

| M-19H-200L | 20000 | 40000 | 62000 | 190 | 54 | +27 | M20 | 200 | 228 | ~ 116 |

・Anti-vibration rubber: High damping rubber

・Housing: Yellow (melamine baked finish)

・Bolts: Unichrome plating

When installing on an inclined surface (permissible gradient: 3° or less), level with 50% or less of the maximum adjustment amount.

(M-19* cannot be leveled up when it is installed at an angle. Please use it for fine adjustment after jacking up.)

| Part number | Minimum load N. | Maximum load N. | spring constant N/mm | φD1 | (H) | (H) Level adjustment amount | d | L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

| MY-10B | 3150 | 6300 | 4600 | 100 | 39 | +18 | M12 | 90 | 118 | ~ 39 |

| MY-10B-120L | 3150 | 6300 | 4600 | 100 | 39 | +18 | M12 | 120 | 148 | ~ 69 |

| MY-10B-200L | 3150 | 6300 | 4600 | 100 | 39 | +18 | M12 | 200 | 228 | ~ 149 |

| MY-14B-90L | 6300 | 12500 | 9200 | 140 | 47 | +19 | M16 | 90 | 127 | ~ 35 |

| MY-14B | 6300 | 12500 | 9200 | 140 | 47 | +19 | M16 | 120 | 157 | ~ 65 |

| MY-14B-200L | 6300 | 12500 | 9200 | 140 | 47 | +19 | M16 | 200 | 237 | ~ 145 |

| MY-19B | 12500 | 25000 | 18300 | 190 | 56 | +25 | M20 | 120 | 164 | ~ 51 |

| MY-19B-200L | 12500 | 25000 | 18300 | 190 | 56 | +25 | M20 | 200 | 244 | ~ 131 |

| Part number | Minimum load N. | Maximum load N. | spring constant N/mm | φD1 | (H) | (H) Level adjustment amount | d | L. | TH | Attachable bed thickness |

|---|---|---|---|---|---|---|---|---|---|---|

| MY-10H-90L | 7500 | 15000 | 23000 | 100 | 35 | +22 | M12 | 90* | 107 | ~ 28 |

| MY-10H | 7500 | 15000 | 23000 | 100 | 35 | +22 | M12 | 120 | 137 | ~ 58 |

| MY-10H-200L | 7500 | 15000 | 23000 | 100 | 35 | +22 | M12 | 200 * | 217 | ~ 138 |

| MY-14H-90L | 15000 | 30000 | 46000 | 140 | 42 | +24 | M16 | 90* | 111 | ~ 19 |

| MY-14H | 15000 | 30000 | 46000 | 140 | 42 | +24 | M16 | 120 | 141 | ~ 49 |

| MY-14H-200L | 15000 | 30000 | 46000 | 140 | 42 | +24 | M16 | 200 * | 221 | ~ 129 |

| MY-19H | 20000 | 40000 | 62000 | 190 | 54 | +27 | M20 | 120 | 148 | ~ 36 |

| MY-19H-200L | 20000 | 40000 | 62000 | 190 | 54 | +27 | M20 | 200 * | 228 | ~ 116 |

*When using mounts of different sizes according to the load of the supporting part, select so that the natural frequencies are the same.

*When selecting from the natural frequency, apply when the excitation force of the machine is generated in the vertical direction.

The A type has a very soft anti-vibration rubber part.

It is effective when more anti-vibration effect than the B type is required, but please note that the vibration of the machine may increase if it is attached to a machine with a large excitation force.

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry