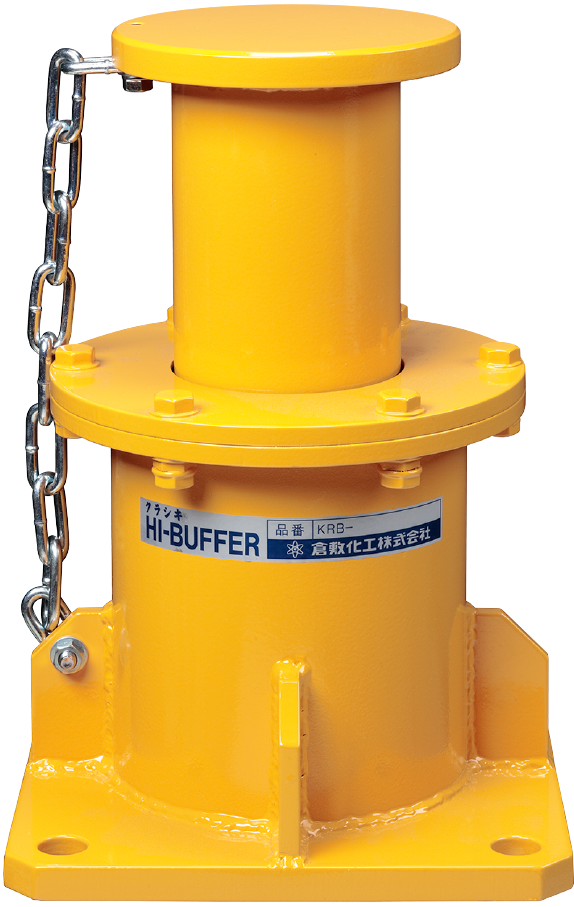

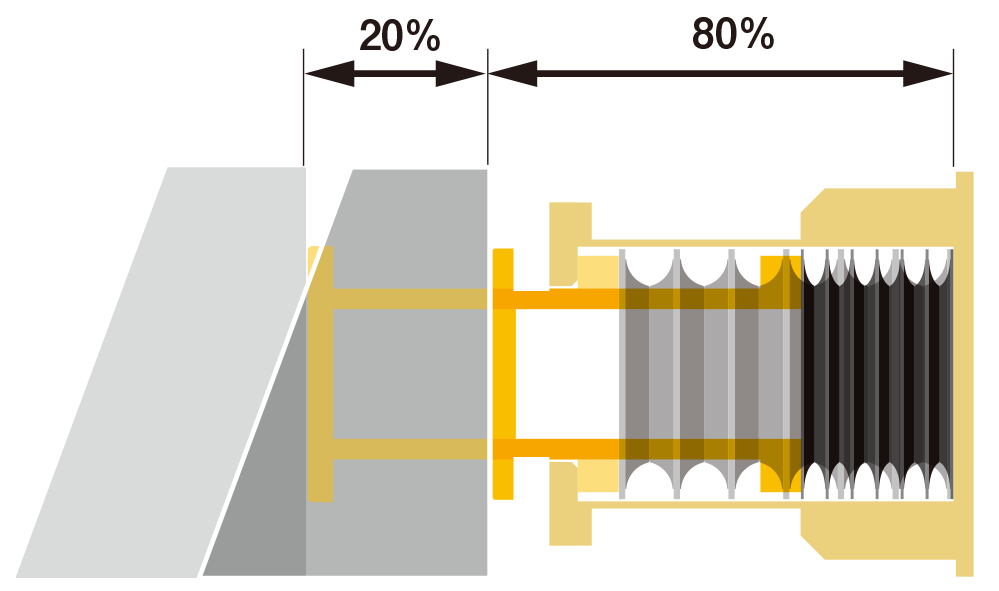

The special synthetic rubber and ideal rubber shape show high energy absorption capacity.

Maintains excellent buffering performance in the temperature range from -30°C to 80°C.

Since the cushioning pad is sealed inside the casing, it prevents the intrusion of foreign substances such as sunlight, ozone, and gravel that cause deterioration of the rubber, and improves durability.

*Maintenance such as oil and grease up is not required.

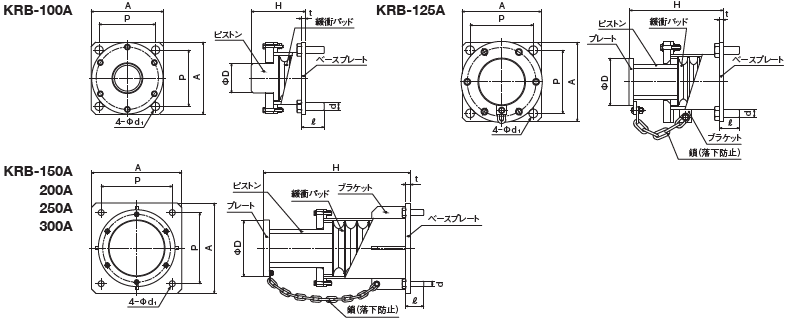

| Product number | D. mm | A. mm | P. mm | t mm | d1_ mm | Attached bolt d-ℓ | H. mm | Energy absorption capacity kJ {kgf-m} | Maximum stroke mm | Maximum impact force kN {tonf} | Product mass kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| KRB-100A-2 | 65 | 160 | 125 | 9 | 18 | M16-50 | 120 | 1.6 { 160 } | 20.6 | 235 { 24 } | 9 |

| KRB-100A-3 | 65 | 160 | 125 | 9 | 18 | M16-50 | 159 | 2.4 {240} | 30.9 | 235 { 24 } | 10 |

| KRB-100A-4 | 65 | 160 | 125 | 9 | 18 | M16-50 | 198 | 3.1 {320} | 41.2 | 235 { 24 } | 11 |

| KRB-100A-5 | 65 | 160 | 125 | 9 | 18 | M16-50 | 237 | 3.9{400} | 51.5 | 235 { 24 } | 12 |

| KRB-125A-3 | 120 | 200 | 160 | 9 | 22 | M20-60 | 198 | 4.1 {420} | 32.4 | 373 { 38 } | 16 |

| KRB-125A-4 | 120 | 200 | 160 | 9 | 22 | M20-60 | 238 | 5.5 {560} | 43.2 | 373 { 38 } | 17 |

| KRB-125A-5 | 120 | 200 | 160 | 9 | 22 | M20-60 | 278 | 6.9 {700} | 54 | 373 { 38 } | 18 |

| KRB-125A-6 | 120 | 200 | 160 | 9 | 22 | M20-60 | 318 | 8.2 { 840 } | 64.8 | 373 { 38 } | 19 |

| KRB-125A-7 | 120 | 200 | 160 | 9 | 22 | M20-60 | 358 | 9.6 { 980 } | 75.6 | 373 { 38 } | 21 |

| KRB-150A-3 | 160 | 250 | 200 | 16 | 22 | M20-60 | 305 | 8.5 {870} | 52.5 | 490 { 50 } | 32 |

| KRB-150A-4 | 160 | 250 | 200 | 16 | 22 | M20-60 | 365 | 11.4 { 1160 } | 70 | 490 { 50 } | 35 |

| KRB-150A-5 | 160 | 250 | 200 | 16 | 22 | M20-60 | 427 | 14.2 { 1450 } | 87.5 | 490 { 50 } | 38 |

| KRB-150A-6 | 160 | 250 | 200 | 16 | 22 | M20-60 | 488 | 17.1 { 1740 } | 105 | 490 { 50 } | 41 |

| KRB-150A-7 | 160 | 250 | 200 | 16 | 22 | M20-60 | 548 | 19.9 {2030} | 122.5 | 490 { 50 } | 43 |

| KRB-200A-3 | 200 | 315 | 250 | 16 | 26 | M24-70 | 377 | 16.2 { 1650 } | 60 | 706 { 72 } | 58 |

| KRB-200A-4 | 200 | 315 | 250 | 16 | 26 | M24-70 | 449 | 21.6 {2200} | 80 | 706 { 72 } | 64 |

| KRB-200A-5 | 200 | 315 | 250 | 16 | 26 | M24-70 | 523 | 27.0 {2750} | 100 | 706 { 72 } | 70 |

| KRB-200A-6 | 200 | 315 | 250 | 16 | 26 | M24-70 | 595 | 32.4 {3300} | 120 | 706 { 72 } | 75 |

| KRB-200A-7 | 200 | 315 | 250 | 16 | 26 | M24-70 | 669 | 37.8 {3850} | 140 | 706 { 72 } | 81 |

| KRB-200A-8 | 200 | 400 | 315 | 22 | 26 | M24-70 | 747 | 43.1 {4400} | 160 | 706 { 72 } | 104 |

| KRB-200A-9 | 200 | 400 | 315 | 22 | 26 | M24-70 | 821 | 48.5 { 4950 } | 180 | 706 { 72 } | 110 |

| KRB-200A-10 | 200 | 400 | 315 | 22 | 26 | M24-70 | 893 | 53.9 {5500} | 200 | 706 { 72 } | 115 |

| KRB-250A-4 | 250 | 400 | 315 | 22 | 26 | M24-80 | 490 | 33.3 {3400} | 88 | 980 { 100 } | 114 |

| KRB-250A-5 | 250 | 400 | 315 | 22 | 26 | M24-80 | 570 | 41.7 { 4250 } | 110 | 980 { 100 } | 126 |

| KRB-250A-6 | 250 | 400 | 315 | 22 | 26 | M24-80 | 651 | 50.0 { 5100 } | 132 | 980 { 100 } | 133 |

| KRB-250A-7 | 250 | 400 | 315 | 22 | 26 | M24-80 | 731 | 58.3 {5950} | 154 | 980 { 100 } | 142 |

| KRB-250A-8 | 250 | 400 | 315 | 22 | 26 | M24-80 | 812 | 66.7 { 6800 } | 176 | 980 { 100 } | 151 |

| KRB-250A-9 | 250 | 400 | 315 | 22 | 26 | M24-80 | 892 | 75.0 { 7650 } | 198 | 980 { 100 } | 160 |

| KRB-250A-10 | 250 | 400 | 315 | 22 | 26 | M24-80 | 973 | 83.4 {8500} | 220 | 980 { 100 } | 169 |

| KRB-300A-4 | 300 | 500 | 400 | 25 | 32 | M30-90 | 545 | 53.0 { 5400 } | 96 | 1520 { 155 } | 198 |

| KRB-300A-5 | 300 | 500 | 400 | 25 | 32 | M30-90 | 631 | 66.2 {6750} | 120 | 1520 { 155 } | 212 |

| KRB-300A-6 | 300 | 500 | 400 | 25 | 32 | M30-90 | 717 | 79.4 {8100} | 144 | 1520 { 155 } | 227 |

| KRB-300A-7 | 300 | 500 | 400 | 25 | 32 | M30-90 | 804 | 92.7 { 9450 } | 168 | 1520 { 155 } | 241 |

| KRB-300A-8 | 300 | 500 | 400 | 25 | 32 | M30-90 | 890 | 106 { 10800 } | 192 | 1520 { 155 } | 256 |

| KRB-300A-9 | 300 | 500 | 400 | 25 | 32 | M30-90 | 977 | 119 { 12150 } | 216 | 1520 { 155 } | 270 |

| KRB-300A-10 | 300 | 600 | 500 | 25 | 32 | M30-90 | 1063 | 132 { 13500 } | 240 | 1520 { 155 } | 285 |

| KRB-300A-12 | 300 | 600 | 500 | 25 | 32 | M30-90 | 1246 | 159 { 16200 } | 288 | 1520 { 155 } | 347 |

| KRB-300A-14 | 300 | 600 | 500 | 25 | 32 | M30-90 | 1419 | 185 { 18900 } | 336 | 1520 { 155 } | 376 |

| KRB-300A-16 | 300 | 600 | 500 | 25 | 32 | M30-90 | 1591 | 212 { 21600 } | 384 | 1520 { 155 } | 405 |

| KRB-300A-18 | 300 | 600 | 500 | 25 | 32 | M30-90 | 1764 | 238 { 24300 } | 432 | 1520 { 155 } | 433 |

*Painting: Polyurethane resin paint

(1) Install so that the impact is received vertically on the plane of the piston head.

(2) Install on a flat mounting plate with high rigidity.

(3) Use the supplied bolts for mounting.

(1) In order to know that Shock Absorber are working properly, check if there is any abnormal noise from Shock Absorber or the building at the time of collision.

(2) If you find any abnormal noise or deformation of the shock Shock Absorber due to impact, replace it immediately.

(1) If the collision frequency is high (more than 10 times a day), select the maximum stroke as about half of the standard table.

(2) When mounting on both sides, use the same D dimension in the standard table, and make sure that the total number of buffer pads does not exceed the standard value.

Also, do not place it facing the KUB type.

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry