At maximum load, the natural frequency is 3 to 4 Hz, demonstrating anti-vibration performance close to PSB type air springs.

It can insulate the surging phenomenon seen in coil springs and provide soundproofing effects.

The rubber film is relatively thick, and the rubber itself has a damping effect.

Side walls are made of metal, which increases safety in the event of a contact accident.

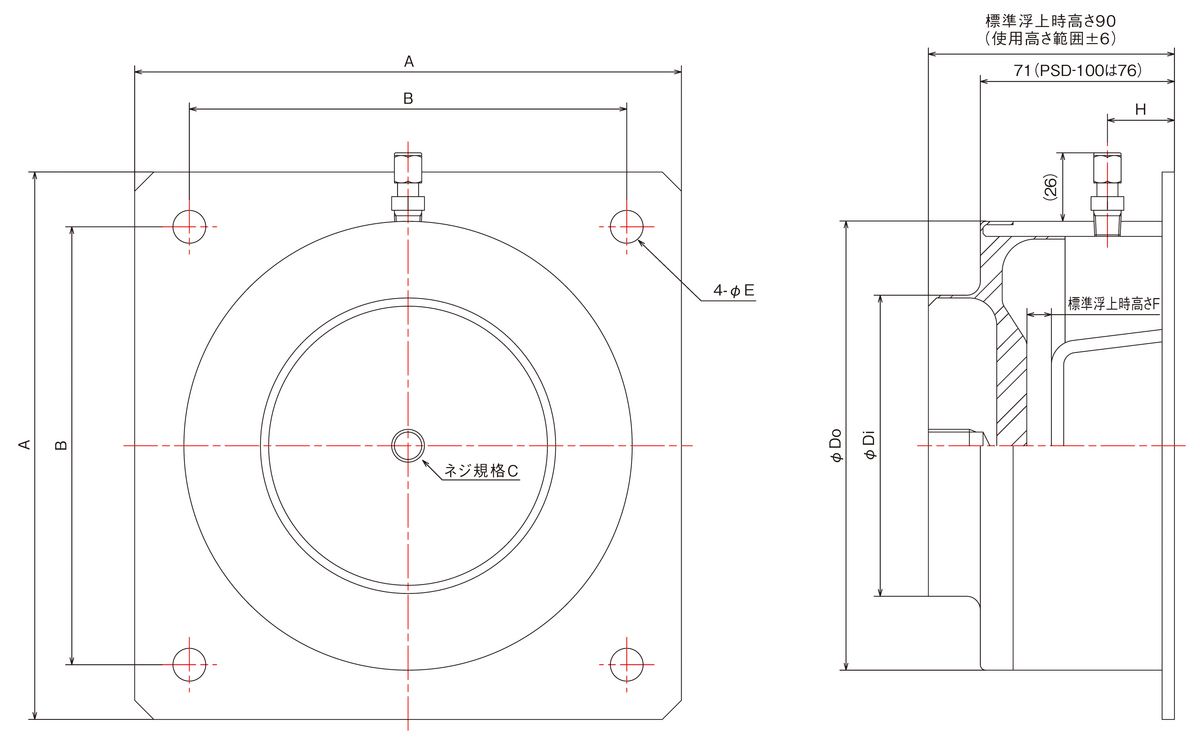

The height of the product is the same for all sizes and is designed as low as 90mm. For this reason, the height of the equipment is not so high, and it is possible to use different sizes together.

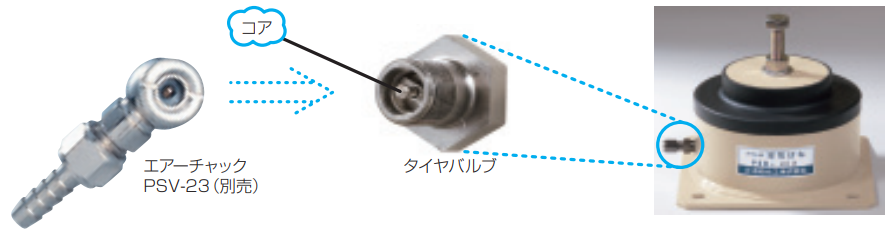

This product is an air-sealed type, and a tire valve (for automobiles) is attached to the main body to seal the air. Air can be easily filled with an optional air chuck (air sealing tool).

In addition, air can be easily released by pressing the core of the tire valve, making it easy to adjust the level.

The internal stopper allows the device to be supported even without air, making it easy to install and maintain.

| Part number | Working load range (N) minimum | Working load range (N) maximum | A. | B. | C. | D₀ | Di | E. | F. | H. | Product weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PSD-100 | 500 | 1000 | 125 | 100 | M10 × depth 10 | 100 | 38 | 10 | 6 | 23 | 1.9 |

| PSD-200 | 1000 | 2000 | 125 | 100 | M12 × depth 15 | 100 | 60 | 10 | 9 | 23 | 1.8 |

| PSD-400 | 2000 | 4000 | 160 | 125 | M12 × depth 15 | 138 | 90 | 12 | 9 | 25 | 3.5 |

| PSD-600 | 4000 | 6000 | 200 | 160 | M12 × depth 15 | 164 | 110 | 12 | 9 | 25 | 5.3 |

| PSD-1000 | 6000 | 10000 | 250 | 200 | M16 × depth 15 | 212 | 150 | 14 | 9 | 26 | 7.0 |

| PSD-2000 | 10000 | 20000 | 350 | 315 | M16 × depth 15 | 314 | 240 | 14 | 9 | 26 | 15.5 |

*F is the distance to the stopper at standard height (reference value).

| Part number | Accessories |

|---|---|

| PSD-100 | Hex bolt M10X40L, hex nut, flat washer 1 each |

| PSD-200 | Hex bolt M12X50L, hex nut, flat washer 1 each |

| PSD-400 | Hex bolt M12X50L, hex nut, flat washer 1 each |

| PSD-600 | Hex bolt M12X50L, hex nut, flat washer 1 each |

| PSD-1000 | Hexagonal bolt M16X60L, hexagonal nut, flat washer - 1 each |

| PSD-2000 | Hexagonal bolt M16X60L, hexagonal nut, flat washer - 1 each |

*Anchor bolts are not included.

1. Never inject air when the air spring is unloaded.

2. Be sure to remove the air before removing the air spring from the equipment or moving the equipment.

3. Be careful not to damage the diaphragm of the air spring during installation and use.

Install a protective cover if there is a risk of foreign matter coming in contact with the diaphragm or tire valve.

4. The ambient temperature for use should be -20°C to +60°C.

In environments exceeding 40°C, the life of air springs may be shortened.

5. Be careful not to allow acids, alkalis, organic solvents, lubricating oils, etc. to adhere to the diaphragm.

In the unlikely event that it adheres, wash it with water immediately.

6. Use the air spring height within the range of 90±6mm.

7. If there is a scratch reaching the reinforcement cord on the diaphragm or an abnormal bulge, replace it immediately.

8. Do not raise the pressure above 0.5 MPa even during the air charging process.

At maximum load, the pressure at standard height 90mm is 0.45MPa.

9. There may be brown discoloration near the valve insertion port, but it is not rust.

It is a sealing material that prevents air leakage. Never wipe off. It may not work properly.

Ten. For anti-vibration purposes, do not use air springs for equipment that meets the following conditions.

①: When the operating speed (or operating stroke speed) of the device is close to the natural frequency of the air spring, 3 to 6 Hz.

This is the case, for example, for presses below 500 rpm.

②: For devices whose rotational speed rises and falls very slowly when starting and stopping, and whose resonance state continues for a long time.

③: Not applicable to (1), but the excitation force of the equipment is strong, and as a result, the amplitude of the air spring becomes excessive at the normal rotation speed.

Air compressors, blowers, refrigerators, generators, printers, transformers, and other equipment

* Basically, it can be used for the above equipment, but it may not be used for some equipment and under some usage conditions. See usage notes.

In addition, additional mass, dampers, stoppers, etc. may be required in actual use.

balances, surface roughness meters, roundness meters, three-dimensional measuring instruments, other precision measuring instruments, testing machines

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry