・Ideal for vibration isolation of lightweight equipment.

・The natural frequency is 4 to 5Hz, which is superior to anti-vibration rubber.

・It is a sealed type equipped with a tire valve, so level adjustment is easy.

・The product height is low and does not take up space.

・The built-in stopper can support the weight of the device even when there is no air in it, making installation and maintenance easy.

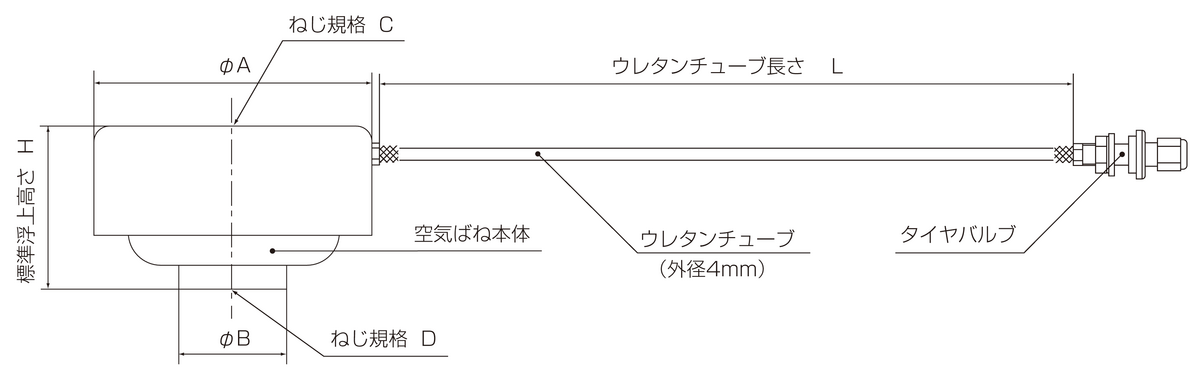

| Part number | Working load range (N) minimum | Working load range (N) maximum | ФA | ФB | C. | D. | H. | L. |

|---|---|---|---|---|---|---|---|---|

| PSL-75 | 250 | 750 | 102 | 40 | M10 x depth 15 | M10 × depth 10 | 60±5 | 500 |

| PSL-150 | 750 | 1500 | 122 | 40 | M10 x depth 15 | M10 × depth 10 | 65±5 | 500 |

*H dimension indicates the standard floating height and its allowable range.

Minimum height (with built-in stopper) is H-10mm.

*The urethane tube L dimension can be changed.

1. Never inject air when the air spring is unloaded.

The air spring has a built-in stopper and can support the device without air. After installing the device, please inflate it.

2. Be sure to remove the air before removing the air spring from the equipment or moving the equipment.

3. Be careful not to subject the air spring body, tire valve, urethane tube, etc. to impact or damage them.

4. The ambient temperature for use should be -20°C to +60°C.

In environments exceeding 40°C, the life of air springs may be shortened.

5. The height of the air spring should be within ±5mm of the standard flying height.

6. Do not raise the pressure above 0.3 MPa even during the air charging process.

7. Please use it for the equipment for the purpose of vibration isolation.

When using for anti-vibration equipment, check in advance the condition of the air spring when the equipment is in operation.

8. If air leaks from the tire valve, re-tighten the valve core with the included screwdriver.

9. For anti-vibration purposes, do not use air springs for equipment that meets the following conditions.

①: When the operating speed (or operating stroke speed) of the device is close to the natural frequency of the air spring, 3 to 6 Hz.

This is the case, for example, for presses below 500 rpm.

②: For devices whose rotational speed rises and falls very slowly when starting and stopping, and whose resonance state continues for a long time.

③: Not applicable to (1), but the excitation force of the equipment is strong, and as a result, the amplitude of the air spring becomes excessive at the normal rotation speed.

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry