構造が簡単であり取付けも容易です。

小形で比較的大きいばね定数が得られるので大きい荷重の支持が可能です。

取付け方向によって、圧縮方向、せん断方向のほか、傾斜方向にも使用でき、広い応用性を持っています。

耐候性に優れ、軽度の耐油性を有します。

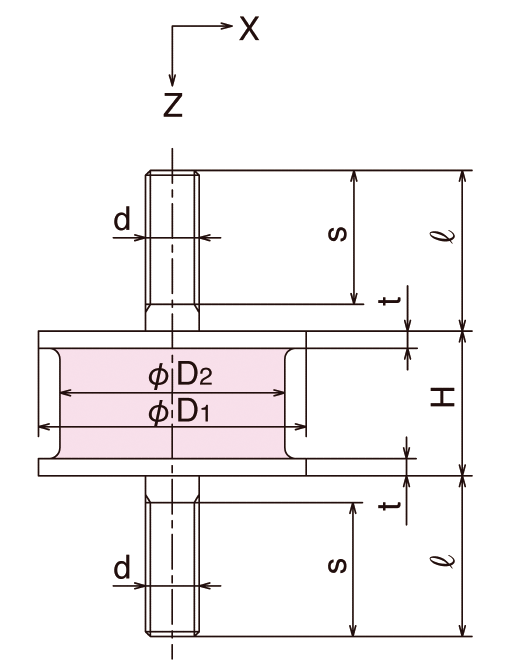

| 品番 | D₁ | D₂ | H | t | d | ℓ | s | Z方向支持荷重 N {kgf} | Z方向許容荷重 N {kgf} | X方向許容荷重 N {kgf} | Z方向ばね定数 Kz N/mm {kgf/cm} | 剛性比 Kx/Kz | 静動比 (参考) | 製品質量 kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KA-10CR | 10 | 10 | 13 | 1 | M4 | 10 | 9 | ~ 34 { 3.5 } | 58 { 5.9 } | 9.8 { 1 } | 22 { 22 } | 0.16 | 1.69 | 0.004 |

| KA-12CR | 12 | 10 | 16 | 2 | M5 | 12 | 11 | ~ 78 { 8 } | 110 { 11 } | 25 { 2.5 } | 41 { 42 } | 0.20 | 1.93 | 0.008 |

| KA-15CR | 15 | 12 | 15 | 2 | M5 | 15 | 12 | ~ 130 { 13 } | 160 { 16 } | 34 { 3.5 } | 74 { 75 } | 0.20 | 1.93 | 0.012 |

| KA-20CR | 20 | 15 | 15 | 2 | M6 | 15 | 13 | ~ 160 { 16 } | 280 { 29 } | 69 { 7 } | 130 { 130 } | 0.15 | 1.93 | 0.019 |

| KA-20-20HCR | 20 | 15 | 20 | 2 | M6 | 15 | 13 | ~ 98 { 10 } | 180 { 18 } | 49 { 5 } | 78 { 80 } | 0.19 | 1.93 | 0.020 |

| KA-25CR | 25 | 20 | 18 | 2.3 | M6 | 18 | 16 | ~ 240 { 24 } | 480 { 49 } | 88 { 9 } | 180 { 180 } | 0.16 | 1.93 | 0.033 |

| KA-25-27HCR | 25 | 20 | 27 | 2.3 | M6 | 18 | 16 | ~ 160 { 16 } | 310 { 32 } | 59 { 6 } | 93 { 95 } | 0.20 | 1.93 | 0.037 |

| KA-30CR | 30 | 25 | 18 | 2.3 | M8 | 24 | 20 | ~ 450 { 46 } | 890 { 91 } | 170 { 17 } | 310 { 320 } | 0.16 | 1.93 | 0.056 |

| KA-30-26HCR | 30 | 25 | 26 | 2.3 | M8 | 24 | 20 | ~ 300 { 31 } | 610 { 62 } | 120 { 12 } | 140 { 145 } | 0.19 | 1.93 | 0.061 |

| KA-35CR | 35 | 30 | 26 | 2.3 | M8 | 24 | 20 | ~ 490 { 50 } | 980 { 100 } | 250 { 25 } | 240 { 240 } | 0.17 | 1.93 | 0.078 |

| KA-35-35HCR | 35 | 30 | 35 | 2.3 | M8 | 24 | 20 | ~ 370 { 38 } | 740 { 75 } | 200 { 20 } | 150 { 150 } | 0.20 | 1.93 | 0.087 |

| KA-40CR | 40 | 34 | 25 | 2.3 | M8 | 30 | 25 | ~ 930 { 95 } | 1810 { 185 } | 360 { 37 } | 340 { 350 } | 0.17 | 1.93 | 0.099 |

| KA-40-33HCR | 40 | 34 | 33 | 2.3 | M8 | 30 | 25 | ~ 540 { 55 } | 1100 { 110 } | 250 { 25 } | 220 { 220 } | 0.19 | 1.93 | 0.11 |

| KA-45CR | 45 | 38 | 34 | 3.2 | M8 | 29 | 25 | ~ 830 { 85 } | 1700 { 170 } | 290 { 30 } | 290 { 300 } | 0.20 | 1.93 | 0.15 |

| KA-45-45HCR | 45 | 38 | 45 | 3.2 | M8 | 29 | 25 | ~ 650 { 66 } | 1300 { 130 } | 210 { 21 } | 170 { 170 } | 0.16 | 1.93 | 0.17 |

| KA-50CR | 50 | 42 | 27 | 3.2 | M10 | 30 | 25 | ~ 1230 { 125 } | 2500 { 250 } | 590 { 60 } | 610 { 620 } | 0.17 | 1.93 | 0.18 |

| KA-50-40HCR | 50 | 42 | 40 | 3.2 | M10 | 30 | 25 | ~ 880 { 90 } | 1800 { 180 } | 390 { 40 } | 270 { 280 } | 0.19 | 1.93 | 0.21 |

六角ナット、スプリングワッシャー各2ヶ付きとします。

ゴム材質はクロロプレンゴム配合とします。

・ポンプ

・送風機

・エンジン

・発電機

・電動機

・圧縮機

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

お見積もり・お問い合わせはお気軽に