Cylindrical composite spring structure combining rubber and coil springs provides a soft spring with large deflection.

Composite spring of metal spring and special synthetic rubber provides high load performance without buckling.

The use of special synthetic rubber with a high loss factor provides excellent reduction in resonance amplitude.

There is no surging phenomenon seen when using a metal spring alone, and no noise is generated. In addition, it has excellent shock absorption performance due to its special structure.

It is perfected by advanced shape design technology and compounding technology, so it is extremely resistant to mechanical deterioration during use and chemical deterioration due to oxygen, ozone, chemicals, etc.

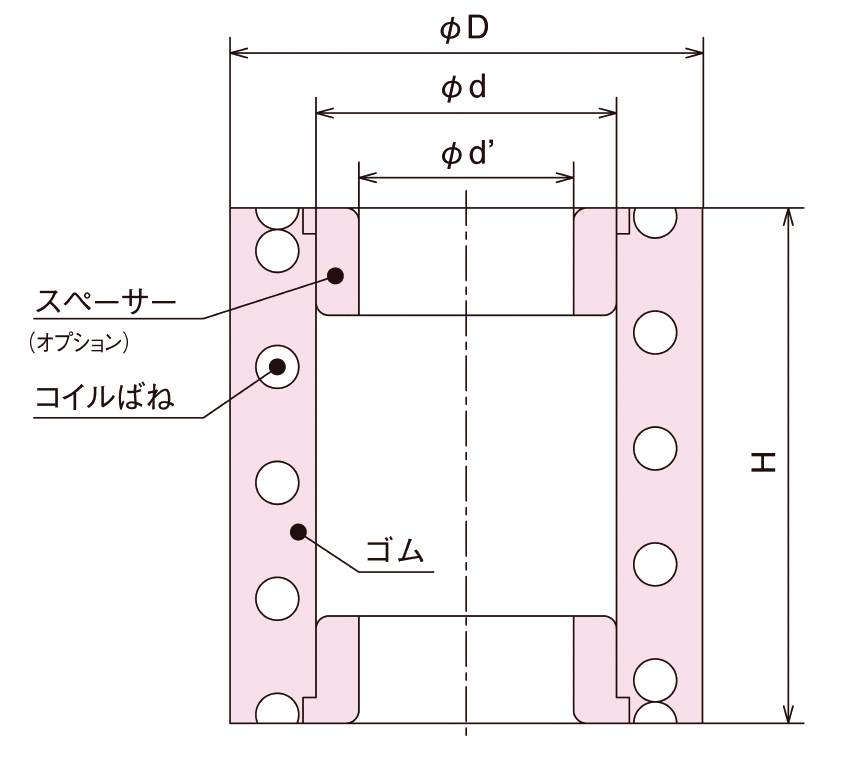

It can be installed by placing the installation guide on the inner diameter Anti-vibration rubber and placing the machine on it. If the inner diameter is too large, use a spacer. We accept it separately.

| Part number | Outline D | Inner diameter d {d'} | Free length H | Allowable load N {kgf} | Spring constant N/mm {kgf/cm} | static dynamic ratio (reference) | Product mass kg |

|---|---|---|---|---|---|---|---|

| KR54-35 | 54 | 40 | 100 | 350 { 36 } | 34 { 35 } | 1.46 | 0.17 |

| KR65-80 | 65 | 44 | 100 | 940 { 96 } | 78 { 80 } | 1.67 | 0.31 |

| KR70-40 | 70 | 54 | 120 | 570 { 58 } | 39 { 40 } | 1.46 | 0.34 |

| KR70-65 | 70 | 48 | 145 | 1130 { 115 } | 64 { 65 } | 1.67 | 0.55 |

| KR85-90 | 85 | 60 | 120 | 1300 { 130 } | 88 { 90 } | 1.58 | 0.64 |

| KR85-100 | 85 | 60 | 120 | 1420 { 145 } | 98 { 100 } | 1.67 | 0.64 |

| KR85-125 | 85 | 60 | 120 | 1800 { 180 } | 123 { 125 } | 1.93 | 0.65 |

| KR90-100 | 90 | 60 | 150 | 1800 { 180 } | 98 { 100 } | 1.46 | 0.97 |

| KR90-125 | 90 | 60 | 150 | 2210 { 225 } | 123 { 125 } | 1.93 | 0.99 |

| KR90-150 | 90 | 60 | 150 | 2600 { 270 } | 150 { 150 } | 2.09 | 1.0 |

| KR120-60 | 120 | 94 | 230 | 1600 { 160 } | 59 { 60 } | 1.46 | 1.7 |

| KR120-90 | 120 | 94 | 230 | 2400 { 240 } | 88 { 90 } | 1.93 | 1.8 |

| KR133-100 | 133 | 94 { 75 } | 260 | 3000 { 310 } | 98 { 100 } | 1.46 | 3.6 |

| KR133-125 | 133 | 94 { 75 } | 260 | 3800 { 390 } | 123 { 125 } | 1.67 | 3.6 |

| KR133-150 | 133 | 94 { 75 } | 260 | 4600 { 470 } | 150 { 150 } | 1.93 | 4.2 |

| KR155-150 | 155 | 108 { 80 } | 270 | 4800 { 490 } | 150 { 150 } | 1.67 | 5.1 |

| KR155-200 | 155 | 108 { 80 } | 270 | 6400 { 650 } | 200 { 200 } | 1.93 | 5.2 |

| KR155-250-155H | 155 | 108 { 80 } | 155 | 4500 { 460 } | 250 { 250 } | 1.46 | 2.9 |

| KR155-300-155H | 155 | 108 { 80 } | 155 | 4900 { 500 } | 290 { 300 } | 1.67 | 3.0 |

| KR155-360-155H | 155 | 108 { 80 } | 155 | 6600 { 670 } | 350 { 360 } | 1.93 | 3.0 |

| KR170-450 | 170 | 108 { 80 } | 210 | 10800 { 1100 } | 440 { 450 } | 2.09 | 3.3 |

| KR200-200 | 200 | 144 { 119 } | 335 | 7800 { 800 } | 200 { 200 } | 1.67 | 11 |

| KR200-240 | 200 | 144 { 119 } | 335 | 9400 { 960 } | 240 { 240 } | 1.93 | 11 |

| KR200-285 | 200 | 144 { 119 } | 335 | 11200 { 1140 } | 279 { 285 } | 2.04 | 11 |

| KR240-300 | 240 | 170 { 120 } | 400 | 14100 { 1440 } | 290 { 300 } | 1.93 | 19 |

| KR240-400 | 240 | 170 { 120 } | 400 | 18800 { 1920 } | 390 { 400 } | 2.09 | 19 |

The rubber material shall be weather-resistant synthetic rubber.

| Part number | Inner diameter d' | Compatible product (First part number) | Product mass kg |

|---|---|---|---|

| KR133S | 75 | KR133 | 0.11 |

| KR155S | 80 | KR155, KR170 | 0.16 |

| KR200S | 119 | KR200 | 0.27 |

| KR240S | 120 | KR240 | 0.73 |

If you want to attach it to the top and bottom, please order 2 pieces.

1.If the spacer is attached, install it so that the spacer is not pushed in by the installation guide.

2.The mounting guide should have a tapered tip and an R at the end.

3.If the vibration frequency is 20Hz or more or the amplitude is 14mm or more, it must be made of natural rubber, which generates less heat.

4.The ambient temperature should be -10°C to 50°C.

5.External expansion is about 5% of the outer diameter during normal use.

・Vibration sieve

・Vibration conveyor

・Parts feeder

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry