It has a simple structure and is easy to install.

Since one side is embedded with a nut, the mounting bolt space can be reduced.

Depending on the mounting direction, it can be used not only in the compression direction, shear direction, but also in the tilt direction, and has a wide range of applications.

It is possible to change the hardness and material of the rubber if the quantity is large enough.

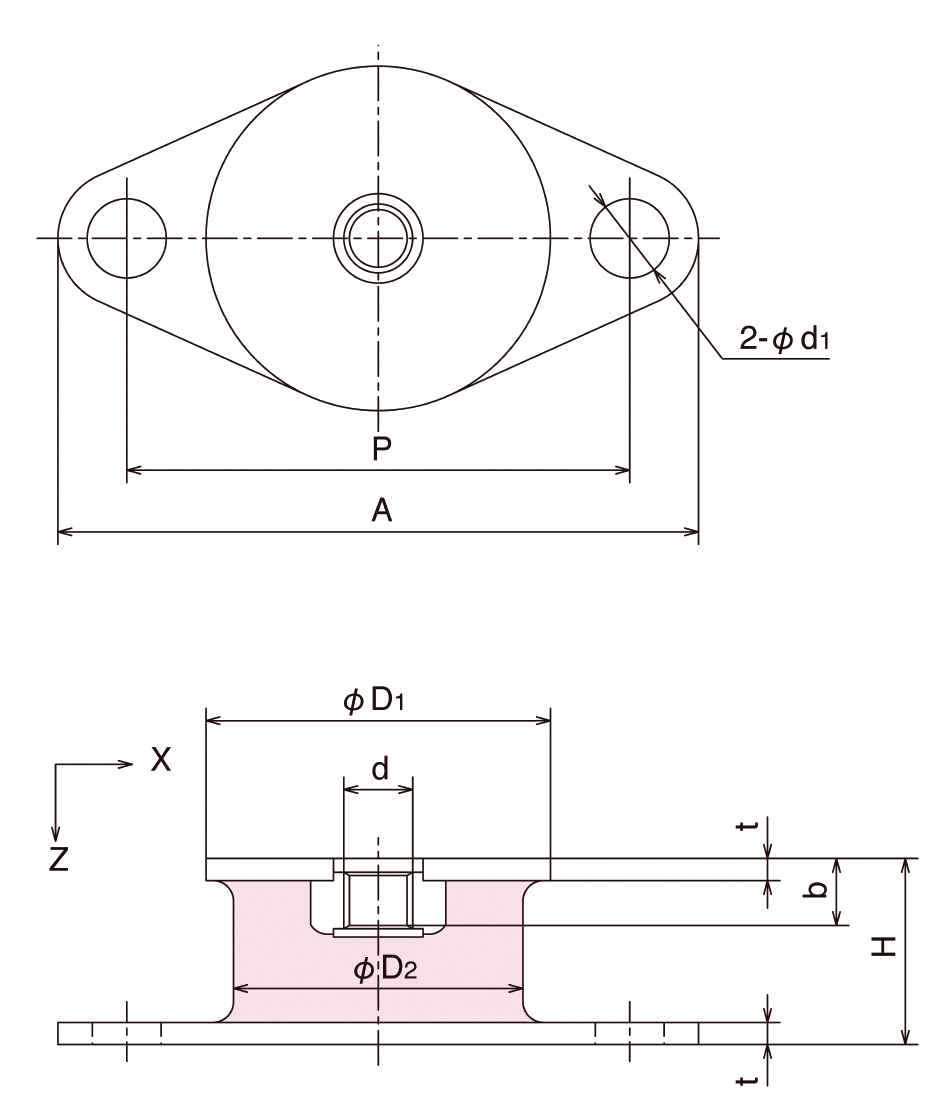

※Please do not tighten more than dimension b.

| Part number | D₁ | D2 | H. | t | d | b | A. | P. | d₁ | Support load in Z direction N {kgf} | Allowable load in Z direction N {kgf} | X-direction allowable load N {kgf} | Z direction spring constant Kz N/mm {kgf/cm} | Stiffness ratio Kx/Kz | static dynamic ratio (reference) | Product mass kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RB-20 | 20 | 15 | 15 | 2 | M6 | 5 | 49 | 36 | 7 | ~ 160 { 16 } | 280 { 29 } | 69 { 7 } | 180 { 180 } | 0.18 | 1.4 | 0.020 |

| RB-20-20H | 20 | 15 | 20 | 2 | M6 | 5 | 49 | 36 | 7 | ~ 98 { 10 } | 180 { 18 } | 49 {5} | 88 { 90 } | 0.22 | 1.4 | 0.021 |

| RB-25 | 25 | 20 | 18 | 2.3 | M6 | 6 | 56 | 42 | 7 | ~ 280 { 29 } | 580 { 59 } | 98 { 10 } | 220 { 220 } | 0.19 | 1.4 | 0.035 |

| RB-25-27H | 25 | 20 | 27 | 2.3 | M6 | 6 | 56 | 42 | 7 | ~ 160 { 16 } | 310 { 32 } | 59 {6} | 110 { 110 } | 0.22 | 1.4 | 0.038 |

| RB-30 | 30 | 25 | 18 | 2.3 | M8 | 7.2 | 62 | 48 | 7 | ~ 830 { 85 } | 1700 { 170 } | 250 { 25 } | 610 { 620 } | 0.15 | 1.4 | 0.068 |

| RB-30-26H | 30 | 25 | 26 | 2.3 | M8 | 7.2 | 62 | 48 | 7 | ~ 370 { 38 } | 760 { 77 } | 150 { 15 } | 180 { 180 } | 0.22 | 1.4 | 0.073 |

| RB-35 | 35 | 30 | 26 | 2.3 | M8 | 7.2 | 69 | 53 | 9 | ~ 550 { 56 } | 1100 { 110 } | 260 { 27 } | 250 { 260 } | 0.24 | 1.4 | 0.068 |

| RB-35-35H | 35 | 30 | 35 | 2.3 | M8 | 7.2 | 69 | 53 | 9 | ~ 450 { 46 } | 890 { 91 } | 210 { 21 } | 150 { 150 } | 0.23 | 1.4 | 0.075 |

| RB-40 | 40 | 34 | 25 | 2.3 | M8 | 7.2 | 76 | 60 | 9 | ~ 700 { 71 } | 1420 { 145 } | 320 { 33 } | 340 { 350 } | 0.23 | 1.4 | 0.086 |

| RB-40-33H | 40 | 34 | 33 | 2.3 | M8 | 7.2 | 76 | 60 | 9 | ~ 560 { 57 } | 1100 { 114 } | 260 { 27 } | 200 { 200 } | 0.24 | 1.4 | 0.094 |

| RB-45 | 45 | 38 | 34 | 3.2 | M8 | 8.1 | 78 | 63 | 9 | ~ 830 { 85 } | 1700 { 170 } | 290 { 30 } | 300 { 310 } | 0.24 | 1.4 | 0.14 |

| RB-45-45H | 45 | 38 | 45 | 3.2 | M8 | 8.1 | 78 | 63 | 9 | ~ 690 { 70 } | 1400 { 140 } | 250 { 25 } | 190 { 190 } | 0.20 | 1.4 | 0.15 |

| RB-50 | 50 | 42 | 27 | 3.2 | M10 | 9.2 | 93 | 73 | 11.5 | ~ 1370 { 140 } | 2700 { 280 } | 470 { 48 } | 670 { 680 } | 0.17 | 1.4 | 0.17 |

| RB-50-40H | 50 | 42 | 40 | 3.2 | M10 | 9.2 | 93 | 73 | 11.5 | ~ 880 { 90 } | 1800 { 180 } | 390 { 40 } | 270 { 280 } | 0.22 | 1.4 | 0.19 |

| RB-55 | 55 | 47 | 40 | 3.2 | M10 | 9.2 | 98 | 78 | 11.5 | ~ 1300 { 130 } | 2500 { 260 } | 440 { 45 } | 340 { 350 } | 0.23 | 1.4 | 0.22 |

| RB-55-54H | 55 | 47 | 54 | 3.2 | M10 | 9.2 | 98 | 78 | 11.5 | ~ 1100 { 110 } | 2300 { 230 } | 390 { 40 } | 240 { 240 } | 0.21 | 1.4 | 0.25 |

| RB-60 | 60 | 52 | 30 | 3.2 | M12 | 11.2 | 104 | 84 | 11.5 | ~ 2060 { 210 } | 4200 { 425 } | 780 { 80 } | 883 { 900 } | 0.19 | 1.4 | 0.25 |

| RB-60-34H | 60 | 52 | 34 | 3.2 | M12 | 11.2 | 104 | 84 | 11.5 | ~ 1670 { 170 } | 3300 { 340 } | 690 { 70 } | 600 { 610 } | 0.21 | 1.4 | 0.26 |

| RB-60-58H | 60 | 52 | 58 | 3.2 | M12 | 11.2 | 104 | 84 | 11.5 | ~ 1300 { 130 } | 2500 { 260 } | 540 { 55 } | 250 { 250 } | 0.21 | 1.4 | 0.30 |

| RB-65 | 65 | 56 | 34 | 3.2 | M12 | 11.2 | 116 | 92 | 11.5 | ~ 2300 { 230 } | 4400 { 450 } | 640 { 65 } | 860 { 880 } | 0.20 | 1.4 | 0.29 |

| RB-65-50H | 65 | 56 | 50 | 3.2 | M12 | 11.2 | 116 | 92 | 11.5 | ~ 1800 { 180 } | 3500 { 360 } | 540 { 55 } | 410 { 420 } | 0.21 | 1.4 | 0.34 |

| RB-75 | 75 | 65 | 42 | 4.5 | M12 | 12.5 | 126 | 102 | 11.5 | ~ 2900 { 300 } | 5900 { 600 } | 880 { 90 } | 960 { 980 } | 0.21 | 1.4 | 0.50 |

| RB-75-63H | 75 | 65 | 63 | 4.5 | M12 | 12.5 | 126 | 102 | 11.5 | ~ 2300 { 230 } | 4500 { 460 } | 740 { 75 } | 450 { 460 } | 0.22 | 1.4 | 0.58 |

| RB-80 | 80 | 70 | 40 | 4.5 | M12 | 12.5 | 136 | 108 | 13.5 | ~ 3240 { 330 } | 6500 { 660 } | 1200 { 120 } | 1040 { 1060 } | 0.18 | 1.4 | 0.57 |

| RB-80-55H | 80 | 70 | 55 | 4.5 | M12 | 12.5 | 136 | 108 | 13.5 | ~ 2600 { 270 } | 5300 { 540 } | 1200 { 125 } | 580 { 590 } | 0.23 | 1.4 | 0.70 |

| RB-90 | 90 | 80 | 50 | 4.5 | M12 | 12.5 | 141 | 117 | 13.5 | ~ 3900 { 400 } | 7800 { 800 } | 1300 { 130 } | 1030 { 1050 } | 0.20 | 1.4 | 0.80 |

| RB-90-76H | 90 | 80 | 76 | 4.5 | M12 | 12.5 | 141 | 117 | 13.5 | ~ 2900 { 300 } | 5900 { 600 } | 1200 { 120 } | 510 { 520 } | 0.22 | 1.4 | 0.90 |

| RB-100 | 100 | 90 | 50 | 4.5 | M16 | 16 | 166 | 134 | 13.5 | ~ 5900 { 600 } | 11800 { 1200 } | 2400 { 240 } | 1440 { 1470 } | 0.20 | 1.4 | 1.0 |

| RB-100-70H | 100 | 90 | 70 | 4.5 | M16 | 16 | 166 | 134 | 13.5 | ~ 3580 { 365 } | 7200 { 730 } | 1720 { 175 } | 800 { 820 } | 0.21 | 1.4 | 1.2 |

| RB-120 | 120 | 110 | 60 | 8 | M16 | 19.5 | 210 | 160 | 18 | ~ 7940 { 810 } | 16000 { 1630 } | 2840 { 290 } | 1810 { 1850 } | 0.18 | 1.4 | 2.3 |

| RB-150 | 150 | 140 | 62 | 8 | M20 | 22.5 | 250 | 190 | 22 | ~ 12700 { 1300 } | 25500 { 2600 } | 5100 { 520 } | 4060 { 4140 } | 0.16 | 1.4 | 3.6 |

*Rubber material is natural rubber compound.

・Pump

・Blower

・Engine

・Generator

・Electric motor

・Compressor

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry