It has a simple structure and is easy to install.

Since it is compact and has a relatively large spring constant, it can support a large load.

Depending on the mounting direction, it can be used in the compression direction, shear direction, and tilt direction, and has a wide range of applications.

It is possible to change the hardness and material of the rubber if the quantity is large enough.

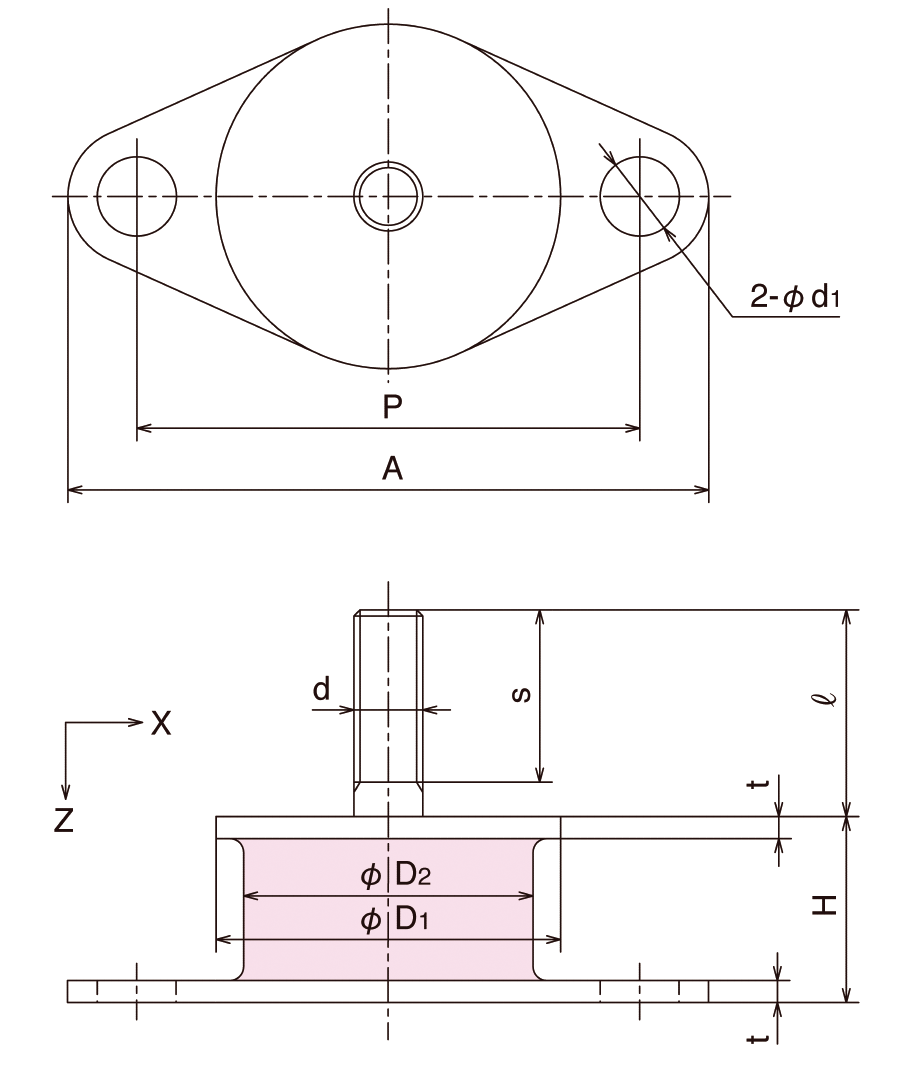

| Part number | D₁ | D2 | H. | t | d | l | s | A. | P. | d₁ | Support load in Z direction N {kgf} | Allowable load in Z direction N {kgf} | X-direction allowable load N {kgf} | Z direction spring constant Kz N/mm {kgf/cm} | Stiffness ratio Kx/Kz | static dynamic ratio (reference) | Product mass kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KB-20 | 20 | 15 | 15 | 2 | M6 | 15 | 13 | 49 | 36 | 7 | ~ 160 { 16 } | 280 { 29 } | 69 { 7 } | 130 { 130 } | 0.15 | 1.4 | 0.021 |

| KB-20-20H | 20 | 15 | 20 | 2 | M6 | 15 | 13 | 49 | 36 | 7 | ~ 98 { 10 } | 180 { 18 } | 49 {5} | 78 { 80 } | 0.19 | 1.4 | 0.022 |

| KB-25 | 25 | 20 | 18 | 2.3 | M6 | 18 | 16 | 56 | 42 | 7 | ~ 240 { 24 } | 480 { 49 } | 88 { 9 } | 180 { 180 } | 0.16 | 1.4 | 0.035 |

| KB-25-27H | 25 | 20 | 27 | 2.3 | M6 | 18 | 16 | 56 | 42 | 7 | ~ 160 { 16 } | 310 { 32 } | 59 {6} | 93 { 95 } | 0.20 | 1.4 | 0.039 |

| KB-25-30H | 25 | 20 | 30 | 2.3 | M6 | 18 | 16 | 56 | 42 | 7 | ~ 190 { 19 } | 370 { 38 } | 59 {6} | 74 { 75 } | 0.18 | 1.4 | 0.040 |

| KB-30 | 30 | 25 | 18 | 2.3 | M8 | 24 | 20 | 62 | 48 | 7 | ~ 450 { 46 } | 890 { 91 } | 170 { 17 } | 310 { 320 } | 0.16 | 1.4 | 0.052 |

| KB-30-26H | 30 | 25 | 26 | 2.3 | M8 | 24 | 20 | 62 | 48 | 7 | ~ 300 { 31 } | 610 { 62 } | 120 { 12 } | 140 { 145 } | 0.19 | 1.4 | 0.057 |

| KB-35 | 35 | 30 | 26 | 2.3 | M8 | 24 | 20 | 69 | 53 | 9 | ~ 490 { 50 } | 980 { 100 } | 250 { 25 } | 240 { 240 } | 0.17 | 1.4 | 0.073 |

| KB-35-35H | 35 | 30 | 35 | 2.3 | M8 | 24 | 20 | 69 | 53 | 9 | ~ 370 { 38 } | 740 { 75 } | 200 { 20 } | 150 { 150 } | 0.20 | 1.4 | 0.081 |

| KB-40 | 40 | 34 | 25 | 2.3 | M8 | 30 | 25 | 76 | 60 | 9 | ~ 930 { 95 } | 1810 { 185 } | 360 { 37 } | 340 { 350 } | 0.17 | 1.4 | 0.092 |

| KB-40-33H | 40 | 34 | 33 | 2.3 | M8 | 30 | 25 | 76 | 60 | 9 | ~ 540 { 55 } | 1100 { 110 } | 250 { 25 } | 220 { 220 } | 0.19 | 1.4 | 0.10 |

| KB-40-40H | 40 | 34 | 40 | 2.3 | M8 | 30 | 25 | 76 | 60 | 9 | ~ 580 { 59 } | 1160 { 118 } | 170 { 17 } | 160 { 160 } | 0.18 | 1.4 | 0.11 |

| KB-45 | 45 | 38 | 34 | 3.2 | M8 | 29 | 25 | 78 | 63 | 9 | ~ 830 { 85 } | 1700 { 170 } | 290 { 30 } | 290 { 300 } | 0.20 | 1.4 | 0.14 |

| KB-45-45H | 45 | 38 | 45 | 3.2 | M8 | 29 | 25 | 78 | 63 | 9 | ~ 650 { 66 } | 1300 { 130 } | 210 { 21 } | 170 { 170 } | 0.16 | 1.4 | 0.16 |

| KB-50 | 50 | 42 | 27 | 3.2 | M10 | 30 | 25 | 93 | 73 | 11.5 | ~ 1230 { 125 } | 2500 { 250 } | 590 { 60 } | 610 { 620 } | 0.17 | 1.4 | 0.18 |

| KB-50-40H | 50 | 42 | 40 | 3.2 | M10 | 30 | 25 | 93 | 73 | 11.5 | ~ 880 { 90 } | 1800 { 180 } | 390 { 40 } | 270 { 280 } | 0.19 | 1.4 | 0.20 |

| KB-55 | 55 | 47 | 40 | 3.2 | M10 | 35 | 30 | 98 | 78 | 11.5 | ~ 1200 { 120 } | 2400 { 242 } | 400 { 41 } | 350 { 360 } | 0.17 | 1.4 | 0.24 |

| KB-55-54H | 55 | 47 | 54 | 3.2 | M10 | 35 | 30 | 98 | 78 | 11.5 | ~ 1100 { 110 } | 2300 { 230 } | 390 { 40 } | 250 { 250 } | 0.16 | 1.4 | 0.26 |

| KB-60 | 60 | 52 | 30 | 3.2 | M12 | 35 | 35 | 104 | 84 | 11.5 | ~ 1860 { 190 } | 3700 { 380 } | 750 { 76 } | 780 { 800 } | 0.16 | 1.4 | 0.27 |

| KB-60-34H | 60 | 52 | 34 | 3.2 | M12 | 35 | 35 | 104 | 84 | 11.5 | ~ 2110 { 215 } | 4200 { 430 } | 930 { 95 } | 650 { 660 } | 0.18 | 1.4 | 0.27 |

| KB-60-58H | 60 | 52 | 58 | 3.2 | M12 | 35 | 35 | 104 | 84 | 11.5 | ~ 1400 { 140 } | 2700 { 280 } | 590 { 60 } | 270 { 280 } | 0.20 | 1.4 | 0.33 |

| KB-65 | 65 | 56 | 34 | 3.2 | M12 | 35 | 35 | 116 | 92 | 11.5 | ~ 2300 { 230 } | 4400 { 450 } | 640 { 65 } | 780 { 800 } | 0.16 | 1.4 | 0.32 |

| KB-65-50H | 65 | 56 | 50 | 3.2 | M12 | 35 | 35 | 116 | 92 | 11.5 | ~ 1800 { 180 } | 3500 { 360 } | 540 { 55 } | 410 { 420 } | 0.17 | 1.4 | 0.37 |

| KB-75 | 75 | 65 | 42 | 4.5 | M12 | 45 | 45 | 126 | 102 | 11.5 | ~ 2900 { 300 } | 5900 { 600 } | 880 { 90 } | 860 { 880 } | 0.16 | 1.4 | 0.54 |

| KB-75-63H | 75 | 65 | 63 | 4.5 | M12 | 45 | 45 | 126 | 102 | 11.5 | ~ 2100 { 210 } | 4100 { 420 } | 710 { 72 } | 380 { 390 } | 0.17 | 1.4 | 0.62 |

| KB-80 | 80 | 70 | 40 | 4.5 | M12 | 45 | 45 | 136 | 108 | 13.5 | ~ 4170 { 425 } | 8300 { 850 } | 2000 { 200 } | 1350 { 1380 } | 0.15 | 1.45 | 0.61 |

| KB-80-55H | 80 | 70 | 55 | 4.5 | M12 | 45 | 45 | 136 | 108 | 13.5 | ~ 2900 { 300 } | 5900 { 600 } | 1100 { 110 } | 660 { 670 } | 0.17 | 1.4 | 0.67 |

| KB-90 | 90 | 80 | 50 | 4.5 | M12 | 45 | 45 | 141 | 117 | 13.5 | ~ 3700 { 380 } | 7500 { 760 } | 1200 { 120 } | 900 { 920 } | 0.16 | 1.4 | 0.79 |

| KB-90-76H | 90 | 80 | 76 | 4.5 | M12 | 45 | 45 | 141 | 117 | 13.5 | ~ 2900 { 300 } | 5900 { 600 } | 1200 { 120 } | 520 { 530 } | 0.17 | 1.4 | 0.94 |

| KB-100 | 100 | 90 | 50 | 4.5 | M16 | 55 | 55 | 166 | 134 | 13.5 | ~ 6200 { 630 } | 12400 { 1260 } | 2500 { 250 } | 1610 { 1640 } | 0.14 | 1.45 | 1.1 |

| KB-100-70H | 100 | 90 | 70 | 4.5 | M16 | 55 | 55 | 166 | 134 | 13.5 | ~ 3580 { 365 } | 7200 { 730 } | 1720 { 175 } | 750 { 760 } | 0.18 | 1.4 | 1.2 |

| KB-120 | 120 | 110 | 60 | 8 | M16 | 51 | 51 | 210 | 160 | 18 | ~ 7700 { 785 } | 15400 { 1570 } | 3090 { 315 } | 2160 { 2200 } | 0.13 | 1.4 | 2.3 |

| KB-150 | 150 | 140 | 62 | 8 | M20 | 57 | 57 | 250 | 190 | 22 | ~ 12700 { 1300 } | 25500 { 2600 } | 5100 { 520 } | 3970 { 4050 } | 0.11 | 1.4 | 3.6 |

Comes with one hexagonal nut and one spring washer.

The rubber material is a natural rubber compound.

・Pump

・Blower

・Engine

・Generator

・Electric motor

・Compressor

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry