建設機械等、上下、水平方向に大きな衝撃荷重のかかる機器の防振に適しています。

構造が簡単で取付けが容易です。

すべての方向に優れた防振効果を発揮します。エンジン等の使用では、通常運転時に特に大きな効果を発揮します。

マウントは予備圧力をかけて取付けますので比較的大きいばね定数が得られ、小形にもかかわらず大きな荷重を支持することが可能です。

マウントは締付けて使用しますので、大きい衝撃荷重がかかる場合でも十分な耐久寿命があります。

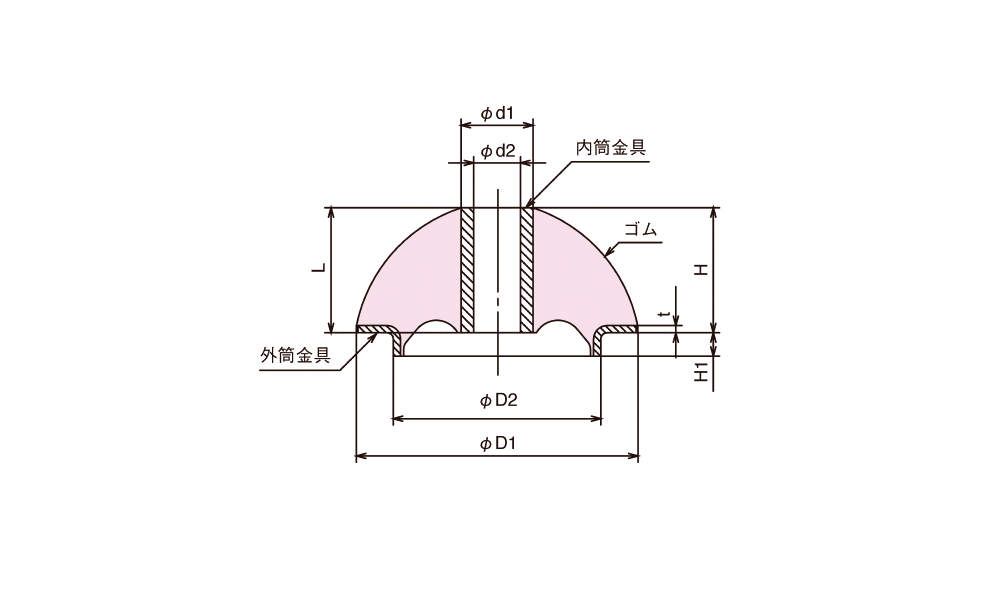

| 品番 | D₁ | D₂ | d₁ | d₂ | L | H | H₁ | t | D₃ | T | H₂ | d | D4 | B | P方向ばね定数 N/mm | Q方向ばね定数 N/mm | 支持荷重 N P方向 最大(1W) | 衝撃荷重 N P方向 | 静動比 (参考) | 製品質量 kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| REM-68A | 68 | 51+0.3-0.5 | 17 | 11 | 30 | 30 | 6.5 | 2 | 51.5+0.5 | 14 | 23 | M10 | 80以上 | C2.5 | 160 | 180 | 270 | 960 | 1.27 | 0.13 |

| REM-68B | 68 | 51+0.3-0.5 | 17 | 11 | 30 | 30 | 6.5 | 2 | 51.5+0.5 | 14 | 23 | M10 | 80以上 | C2.5 | 210 | 240 | 360 | 1260 | 1.35 | 0.13 |

| REM-68C | 68 | 51+0.3-0.5 | 17 | 11 | 30 | 30 | 6.5 | 2 | 51.5+0.5 | 14 | 23 | M10 | 80以上 | C2.5 | 280 | 320 | 480 | 1680 | 1.5 | 0.13 |

| REM-78A | 78 | 58.6+0.3-0.5 | 20 | 13 | 35 | 35 | 7.5 | 2.3 | 59.1+0.5 | 16 | 27 | M12 | 92以上 | C2.5 | 200 | 210 | 390 | 1360 | 1.25 | 0.20 |

| REM-78B | 78 | 58.6+0.3-0.5 | 20 | 13 | 35 | 35 | 7.5 | 2.3 | 59.1+0.5 | 16 | 27 | M12 | 92以上 | C2.5 | 260 | 270 | 510 | 1770 | 1.35 | 0.20 |

| REM-78C | 78 | 58.6+0.3-0.5 | 20 | 13 | 35 | 35 | 7.5 | 2.3 | 59.1+0.5 | 16 | 27 | M12 | 92以上 | C2.5 | 340 | 350 | 660 | 2310 | 1.45 | 0.20 |

| REM-90A | 90 | 66.4+0.3-0.5 | 23 | 15 | 40 | 40 | 7.5 | 2.3 | 66.9+0.5 | 18 | 31 | M14 | 108以上 | C3 | 270 | 240 | 600 | 2100 | 1.25 | 0.30 |

| REM-90B | 90 | 66.4+0.3-0.5 | 23 | 15 | 40 | 40 | 7.5 | 2.3 | 66.9+0.5 | 18 | 31 | M14 | 108以上 | C3 | 350 | 310 | 780 | 2720 | 1.35 | 0.30 |

| REM-90C | 90 | 66.4+0.3-0.5 | 23 | 15 | 40 | 40 | 7.5 | 2.3 | 66.9+0.5 | 18 | 31 | M14 | 108以上 | C3 | 470 | 420 | 1040 | 3650 | 1.5 | 0.30 |

ゴム材質は天然ゴム配合(耐熱仕様)とします。特性は2個1組での値です。

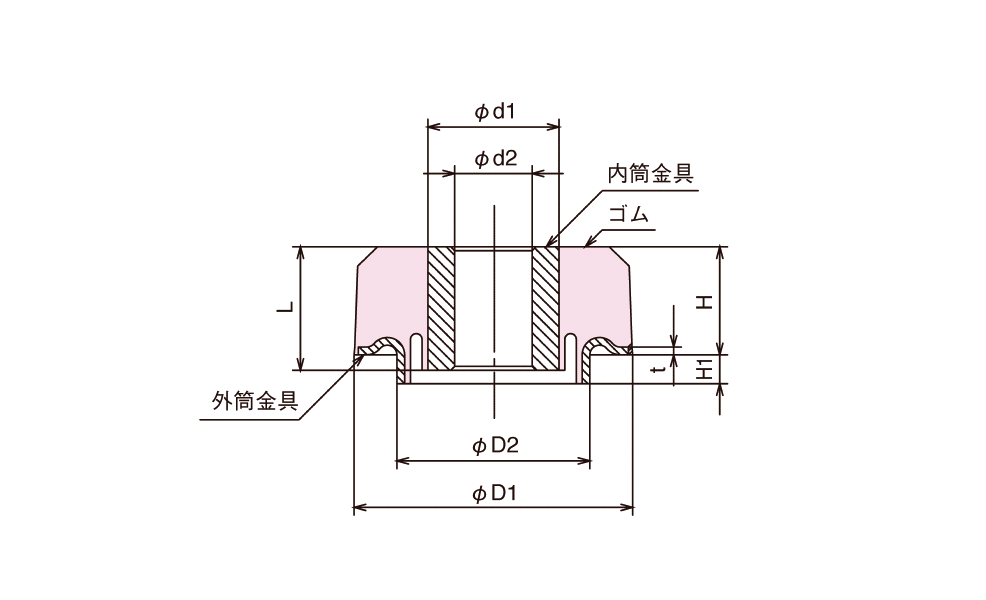

| 品番 | D₁ | D₂ | d₁ | d₂ | L | H | H₁ | t | D₃ | T | H₂ | d | D4 | P方向ばね定数 N/mm | Q方向ばね定数 N/mm | 支持荷重 N P方向 最大(1W) | 衝撃荷重 N P方向 | 静動比 (参考) | 製品質量 kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| REH-60 | 59 | 40+0-0.5 | 24 | 13.2 | 29 | 24.8 | 7.5 | 2 | 40+0.2 | 16 | 21 | M12 | 75以上 | 830 | 440 | 980 | 2940 | 1.35 | 0.17 |

| REH-70A | 72 | 50+0-0.5 | 34 | 20.1 | 32 | 28 | 7.5 | 2 | 50+0.2 | 16 | 24 | M18 | 95以上 | 830 | 390 | 980 | 2940 | 1.25 | 0.28 |

| REH-70B | 72 | 50+0-0.5 | 34 | 20.1 | 32 | 28 | 7.5 | 2 | 50+0.2 | 16 | 24 | M18 | 95以上 | 980 | 490 | 1470 | 4410 | 1.35 | 0.28 |

| REH-70C | 72 | 50+0-0.5 | 34 | 20.1 | 32 | 28 | 7.5 | 2 | 50+0.2 | 16 | 24 | M18 | 95以上 | 1470 | 740 | 1960 | 5880 | 1.5 | 0.29 |

| REH-80A | 78 | 50+0-0.5 | 34 | 20.1 | 32 | 28 | 7.5 | 2 | 50+0.2 | 16 | 24 | M18 | 100以上 | 980 | 440 | 1470 | 4410 | 1.25 | 0.32 |

| REH-80B | 78 | 50+0-0.5 | 34 | 20.1 | 32 | 28 | 7.5 | 2 | 50+0.2 | 16 | 24 | M18 | 100以上 | 1470 | 690 | 1960 | 5880 | 1.4 | 0.32 |

| REH-80C | 78 | 50+0-0.5 | 34 | 20.1 | 32 | 28 | 7.5 | 2 | 50+0.2 | 16 | 24 | M18 | 100以上 | 1960 | 880 | 2940 | 8820 | 1.5 | 0.33 |

| REH-95A | 95 | 60-0.1-0.6 | 38 | 22 | 34.5 | 30 | 9 | 3.2 | 60+0.2 | 19 | 25 | M20 | 120以上 | 2940 | 1320 | 3920 | 11760 | 1.4 | 0.51 |

| REH-95B | 95 | 60-0.1-0.6 | 38 | 22 | 34.5 | 30 | 9 | 3.2 | 60+0.2 | 19 | 25 | M20 | 120以上 | 3920 | 1760 | 4900 | 14700 | 1.5 | 0.51 |

| REH-95C | 95 | 60-0.1-0.6 | 38 | 22 | 34.5 | 30 | 9 | 3.2 | 60+0.2 | 19 | 25 | M20 | 120以上 | 4900 | 2250 | 5880 | 17640 | 1.55 | 0.51 |

| REH-110A | 110 | 62-0.1-0.6 | 38 | 22 | 35.5 | 30 | 9 | 3.2 | 62+0.2 | 19 | 26 | M20 | 135以上 | 3430 | 1570 | 4410 | 13230 | 1.3 | 0.64 |

| REH-110B | 110 | 62-0.1-0.6 | 38 | 22 | 35.5 | 30 | 9 | 3.2 | 62+0.2 | 19 | 26 | M20 | 135以上 | 4900 | 2250 | 5880 | 17640 | 1.5 | 0.65 |

| REH-110C | 110 | 62-0.1-0.6 | 38 | 22 | 35.5 | 30 | 9 | 3.2 | 62+0.2 | 19 | 26 | M20 | 135以上 | 5880 | 2740 | 7350 | 22050 | 1.55 | 0.65 |

ゴム材質は天然ゴム配合(耐熱仕様)とします。特性は2個1組での値です。

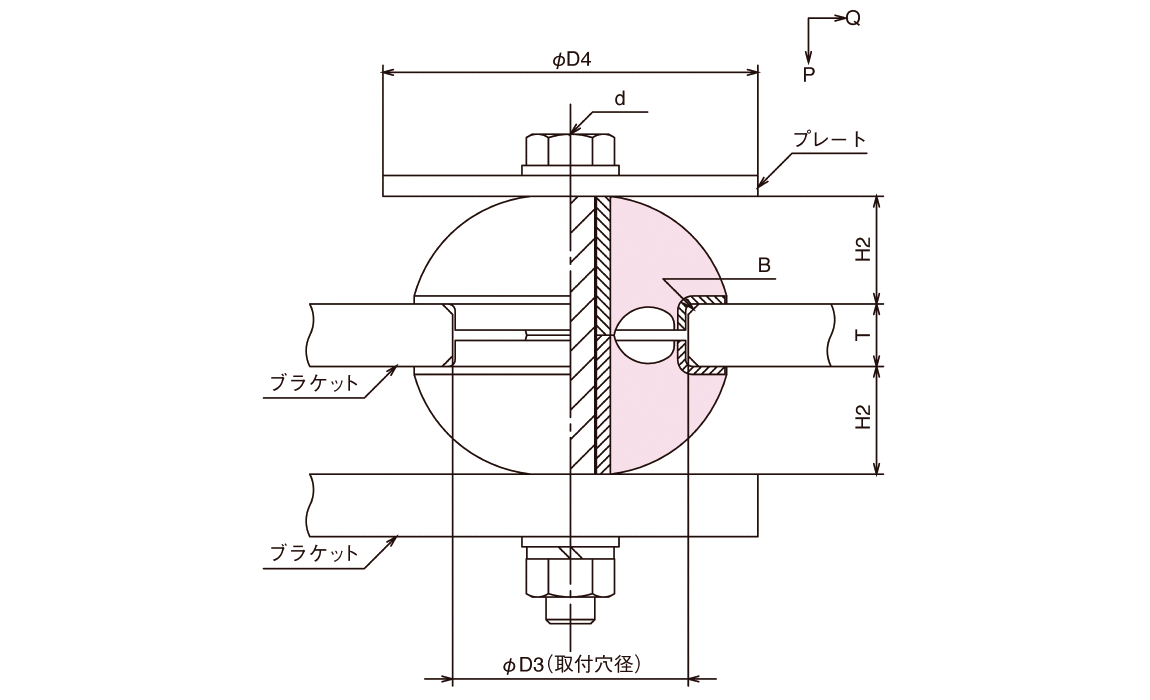

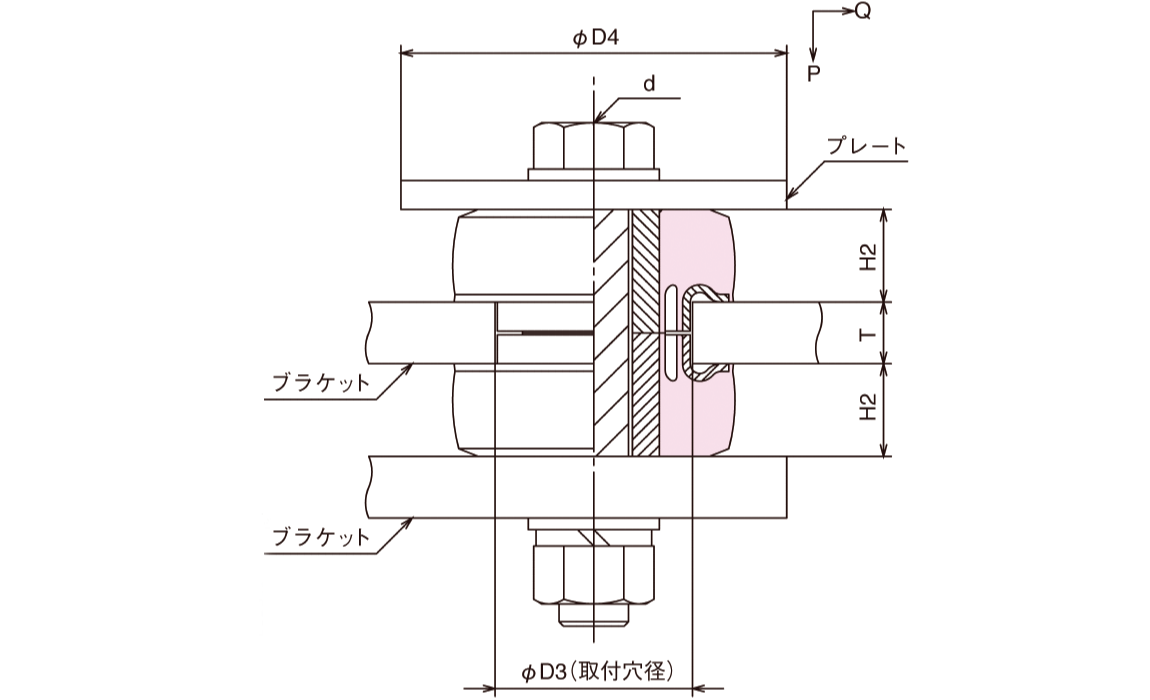

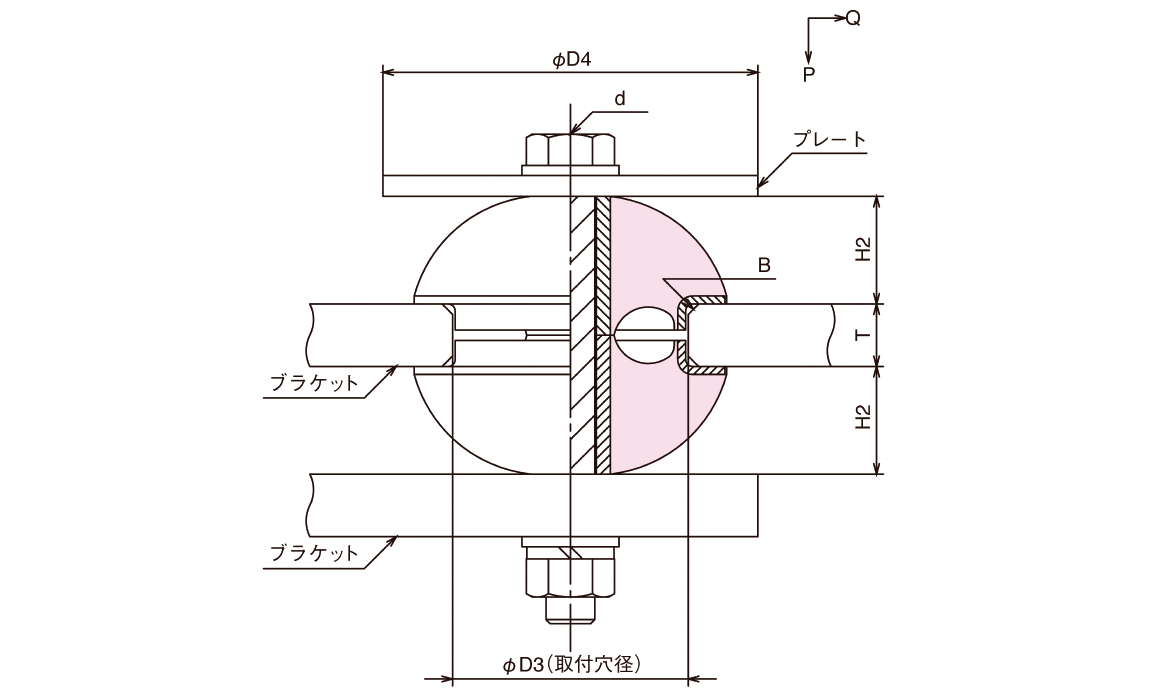

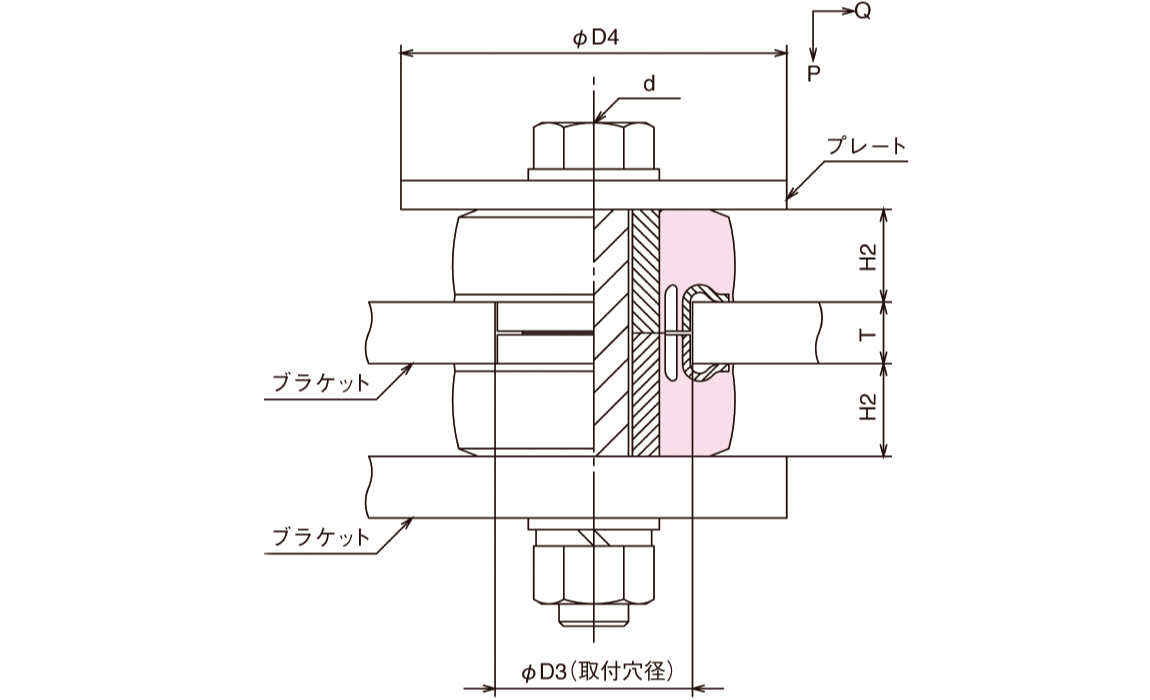

1.マウントは2個1組で使用します。ブラケットの板厚Tの鋼材はお客様の方でご用意ください。

2.支持点荷重のアンバランスが大きい場合は、マウントの使い分けが必要となります。

3.マウントの支持は本体側になっても振動体側になってもどちらでもお使いいただけます。

4.マウントを組付け、ボルトを締めて固定します。締付けは、マウント内筒金具同士が当たるまで行い、運転中に、緩まないようにします。

5.使用可能雰囲気温度は、-30℃~60℃です。

6.ゴム部に対しては、油類の付着および日光の暴露は避けてください。

・建設機械のエンジン、キャビン、燃料タンク、ラジエター

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

お見積もり・お問い合わせはお気軽に