| Flexible type | 1 mountain flexible |

|---|---|

| Usage | Special use for hot water supply |

| Flange | SS400 (Electrogalvanized) Compatible dimensions: JIS10K |

| Water supply/Clean water | ◎ | Sea water | ◎ |

| Hot water supply | ◎ | Oil | ◎ |

| Source | ◎ | Chemical solution | ◎ |

| Chilled water/Cooling water | ◎ | Drainage | ◎ |

| Hot/Cold/Hot water | ◎ | Around the pool circulation | ◎ |

| JIS5K | × |

|---|---|

| SUS flange | 〇:Available |

| Japan Water Association Certified Registered Product | × |

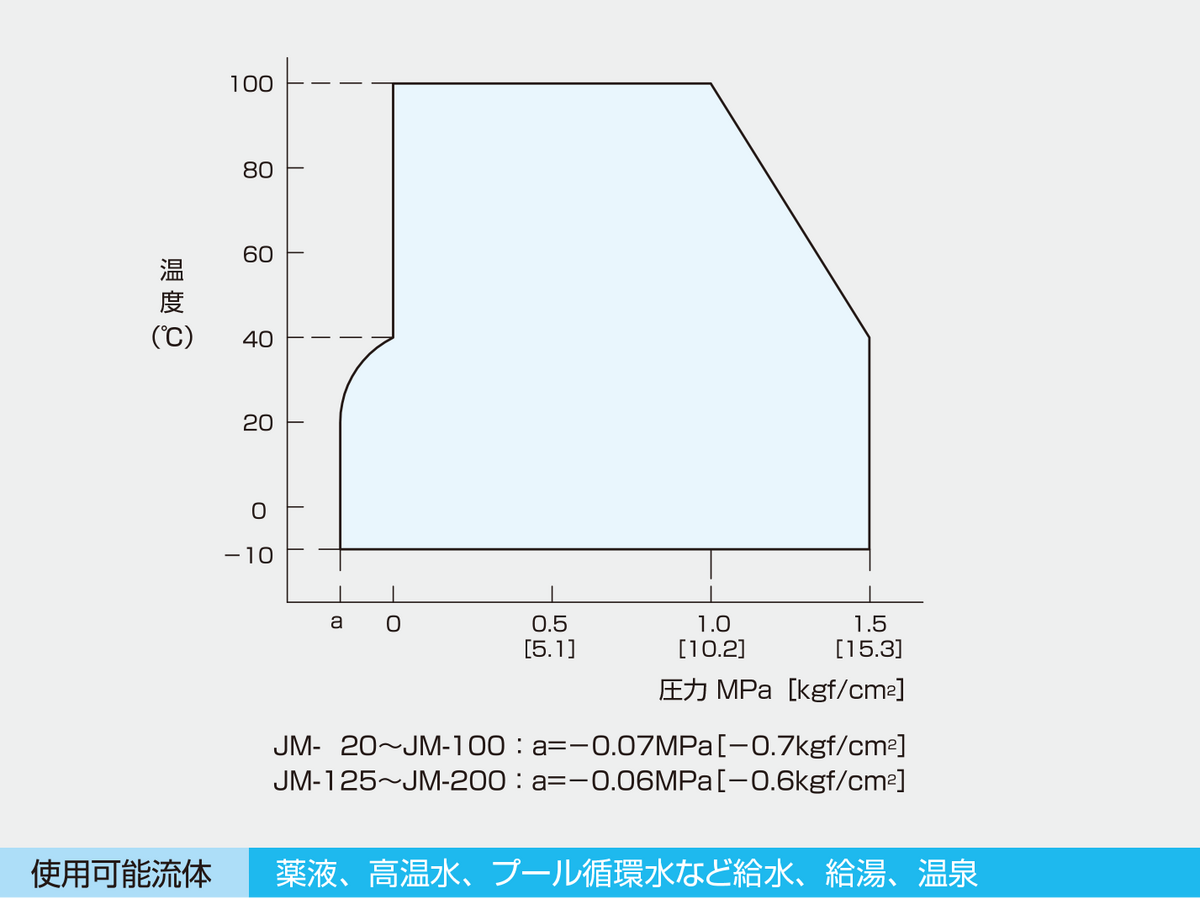

・Can be used for special applications where conventional rubber joints cannot be used.

Chemical resistance: A PTFE tube is used for the wetted part.

Heat resistance: maximum operating temperature of 100°C.

・Durability of 200,000 cycles due to solid ring.

・Vibration is absorbed by the outer rubber.

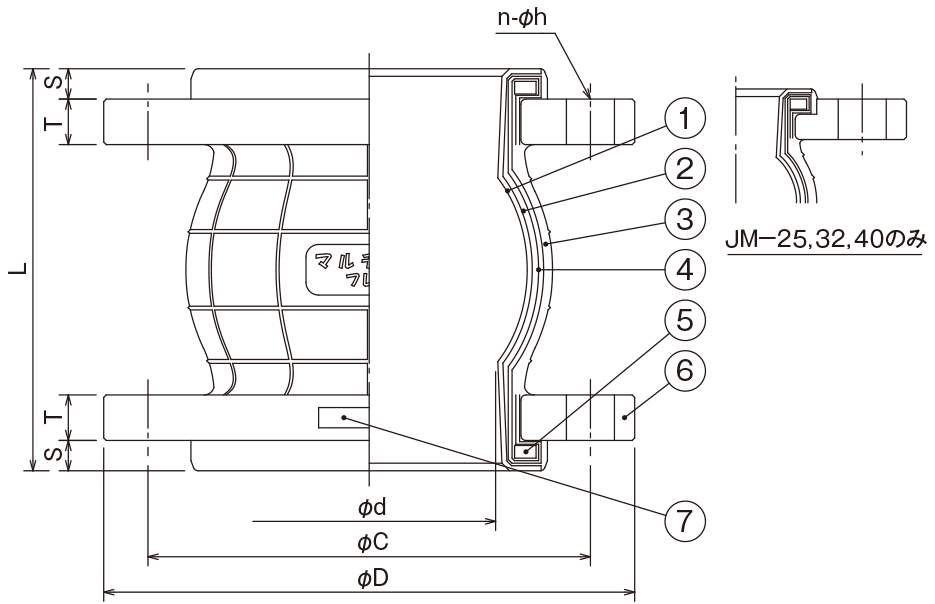

| Name | Material | |

|---|---|---|

| ① | Inner tube | PTFE |

| ② | Inner rubber | Synthetic rubber |

| ③ | External rubber | Synthetic rubber |

| ④ | Reinforcement cord | Synthetic fiber |

| ⑤ | Solid ring | SS400 |

| ⑥ | Flange | SS400 (Electrogalvanized, Compatible dimensions: JIS10K) |

| ⑦ | Caution seal | - |

| Part number | Nominal diameter (A) | Standard dimensions (mm) | Mass (kg) | Mounting Dimensional Tolerance (mm) | Flange spacing i (mm) | Dimensional tolerance during operation (mm) | Recommended bolt diameterNote 1 × Length L | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L. | d | D. | C. | T. | S. | n-h | Between mounting surfaces | Eccentricity e | Shrinkage | Stretch | Eccentricity | Angle of declination (°) | |||||

| JM-20 | 20 | 90 | 20 | 100 | 75 | 14 | 4 | 4-15 | 1.4 | 90±2.5 | ±2.5 | 2.0 to 3.0 | 8 | 4 | 5 | 10 | M12×50L |

| JM-25 | 25 | 90 | 32 | 125 | 90 | 14 | 4 | 4-19 | 2.1 | 90±2.5 | ±2.5 | 2.0 to 3.0 | 8 | 4 | 5 | 15 | M16×55L |

| JM-32 | 32 | 90 | 32 | 135 | 100 | 16 | 4 | 4-19 | 3 | 90±2.5 | ±2.5 | 2.0 to 3.0 | 8 | 4 | 5 | 15 | M16×55L |

| JM-40 | 40 | 97 | 40 | 140 | 105 | 16 | 4 | 4-19 | 3.1 | 97±2.5 | ±2.5 | 2.0 to 3.0 | 8 | 4 | 5 | 15 | M16×55L |

| JM-50 | 50 | 112 | 50 | 155 | 120 | 16 | 10 | 4-19 | 3.9 | 112±2.5 | ±2.5 | 8.0 to 9.0 | 10 | 5 | 5 | 15 | M16×65L |

| JM-65 | 65 | 120 | 65 | 175 | 140 | 18 | 12 | 4-19 | 5.4 | 120±2.5 | ±2.5 | 9.5 to 11.0 | 12 | 6 | 10 | 15 | M16×70L |

| JM-80 | 80 | 142 | 78 | 185 | 150 | 18 | 12 | 8-19 | 5.5 | 142±2.5 | ±2.5 | 9.5 to 11.0 | 14 | 6 | 10 | 15 | M16×70L |

| JM-100 | 100 | 159 | 100 | 210 | 175 | 18 | 12 | 8-19 | 6.9 | 159±2.5 | ±2.5 | 9.5 to 11.0 | 18 | 10 | 10 | 15 | M16×70L |

| JM-125 | 125 | 189 | 123 | 250 | 210 | 20 | 16 | 8-23 | 11 | 189±3.0 | ±3.0 | 13.0 to 15.0 | 20 | 10 | 15 | 15 | M20×80L |

| JM-150 | 150 | 209 | 146 | 280 | 240 | 22 | 16 | 8-23 | 14.4 | 209 ± 3.0 | ±3.0 | 13.0 to 15.0 | 20 | 12 | 15 | 15 | M20×85L |

| JM-200 | 200 | 209 | 196 | 330 | 290 | 22 | 16 | 12-23 | 17.7 | 209 ± 3.0 | ±3.0 | 13.0 to 15.0 | 25 | 14 | 20 | 15 | M20×85L |

*For SUS flange products, please contact your local branch or sales office.

*Note 1: Recommended bolts are not included. Please prepare by yourself.

Please refer to the catalog for installation and use.

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry