It is suitable for anti-vibration equipment such as construction machinery, etc., where large impact loads are applied in the vertical and horizontal directions.

It has a simple structure and is easy to install.

Excellent anti-vibration effect in all directions. In the use of engines, etc., it is particularly effective during normal operation.

Since the mount is attached with preload, a relatively large spring constant can be obtained, and it is possible to support a large load despite its small size.

Since the mount is used after being tightened, it has a sufficient durable life even when a large impact load is applied.

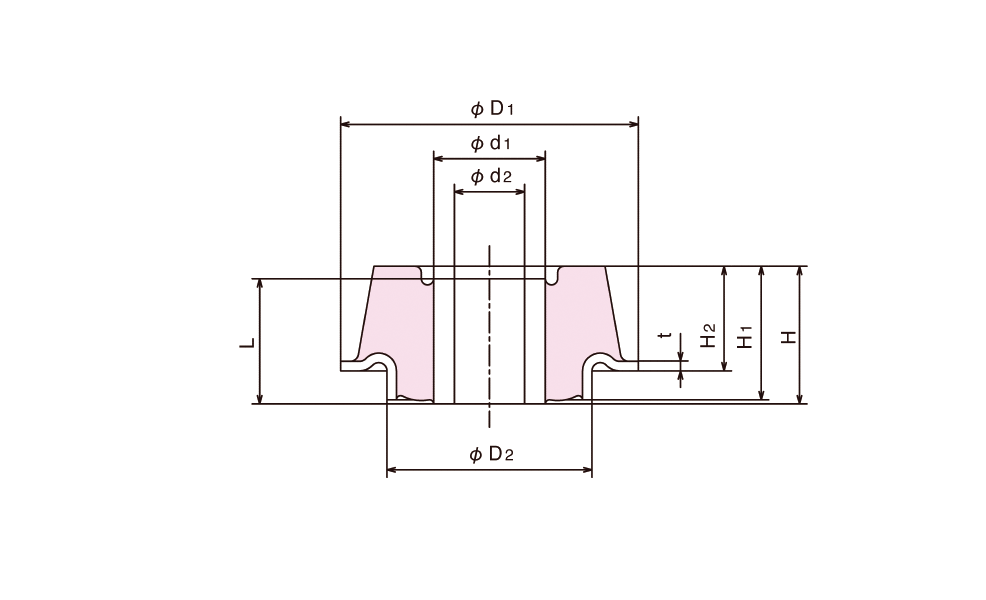

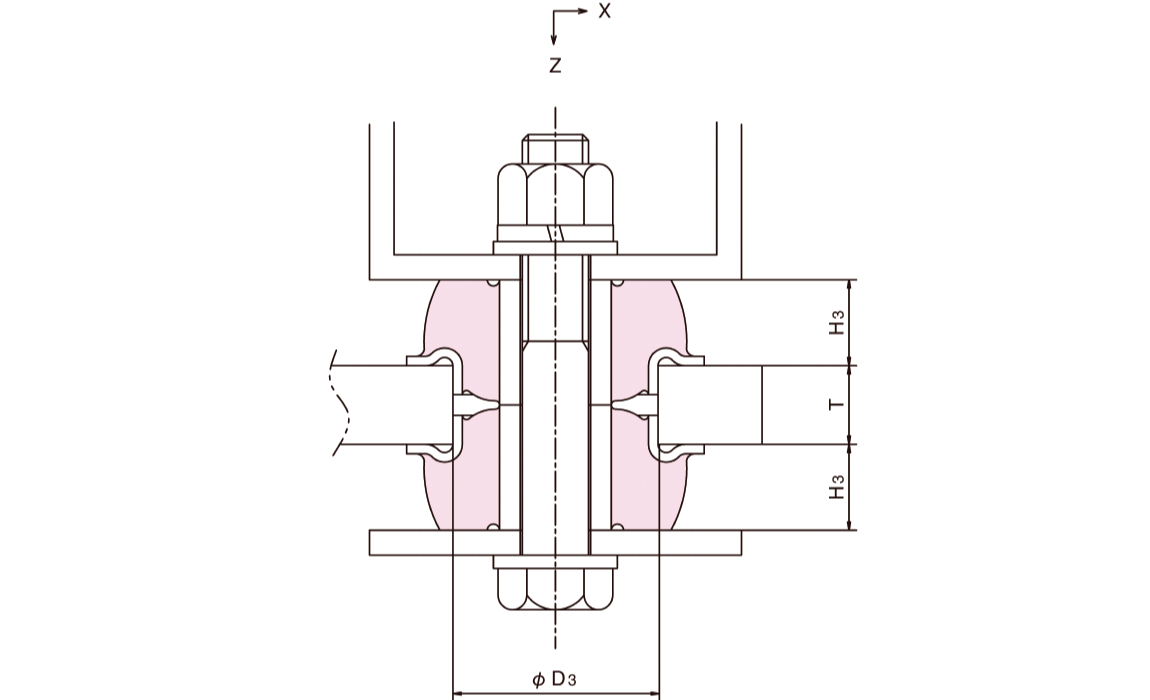

| Part number | D₁ | D2 | d₁ | d2 | L. | H. | H₁ | H₂ | t | D₃ | H₃ | T. | Rubber hardness (JIS) | Support load in Z direction N {kgf} | Z-direction spring constant N/mm {kgf/cm} | X-direction spring constant N/mm {kgf/cm} | Used bolt | static dynamic ratio (reference) | Product mass kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RE-38 | 38 | 25 | 15.5 | 10.5 | 15.6 | 17.1 | 17.1 | 13.6 | 1.6 | 25+0.2 | 11.1 | 9 | 45 | ~ 390 { 40 } | 590 { 600 } | 690 { 700 } | M10 | 1.2 | 0.034 |

| RE-52 | 52 | 35 | 20 | 12.5 | 23.6 | 26.6 | 26.6 | 21.6 | 1.6 | 35+0.2 | 17.6 | 12 | 45 | ~ 780 { 80 } | 690 { 700 } | 690 { 700 } | M12 | 1.2 | 0.088 |

| RE-72(35) | 72 | 50 | 27 | 17 | 30.3 | 33.3 | 32.3 | 25.3 | 2.3 | 50+0.2 | 20.8 | 19 | 35 | ~ 980 { 100 } | 860 { 880 } | 740 { 750 } | M16 | 1.2 | 0.21 |

| RE-72 | 72 | 50 | 27 | 17 | 30.3 | 33.3 | 32.3 | 25.3 | 2.3 | 50+0.2 | 20.8 | 19 | 45 | ~ 1500 { 150 } | 1180 { 1200 } | 980 { 1000 } | M16 | 1.25 | 0.21 |

| RE-72(60) | 72 | 50 | 27 | 17 | 30.3 | 33.3 | 32.3 | 25.3 | 2.3 | 50+0.2 | 20.8 | 19 | 60 | ~ 2000 { 200 } | 1960 { 2000 } | 1770 { 1800 } | M16 | 1.4 | 0.22 |

| RE-98(35) | 98 | 60 | 31 | 21 | 34.8 | 37.8 | 37.3 | 27.3 | 2.3 | 60+0.2 | 22.3 | 25 | 35 | ~ 2000 { 200 } | 1770 { 1800 } | 930 { 950 } | M20 | 1.2 | 0.39 |

| RE-98 | 98 | 60 | 31 | 21 | 34.8 | 37.8 | 37.3 | 27.3 | 2.3 | 60+0.2 | 22.3 | 25 | 45 | ~ 2900 { 300 } | 2450 { 2500 } | 1270 { 1300 } | M20 | 1.2 | 0.39 |

| RE-98(60) | 98 | 60 | 31 | 21 | 34.8 | 37.8 | 37.3 | 27.3 | 2.3 | 60+0.2 | 22.3 | 25 | 60 | ~ 4400 { 450 } | 4220 { 4300 } | 2260 { 2300 } | M20 | 1.45 | 0.40 |

| RE-132 | 132 | 80 | 40 | 25 | 41.2 | 45.2 | 45.2 | 35.2 | 3.2 | 80+0.2 | 28.7 | 25 | 45 | ~ 4400 { 450 } | 3730 { 3800 } | 1470 { 1500 } | M24 | 1.2 | 0.92 |

| RE-132(60) | 132 | 80 | 40 | 25 | 41.2 | 45.2 | 45.2 | 35.2 | 3.2 | 80+0.2 | 28.7 | 25 | 60 | ~ 7800 { 800 } | 6370 { 6500 } | 2650 { 2700 } | M24 | 1.4 | 0.94 |

The rubber material is natural rubber compound. Properties are values in pairs.

1.Two mounts are used in pairs. Customers are requested to prepare the steel materials with plate thickness T for the bracket.

2.If the imbalance of the support point load is large, it is necessary to use different mounts.

3.The mount support can be used either on the main body side or on the vibrating body side.

4.Assemble the mount and tighten the bolts. Tighten until the metal fittings inside the mount come into contact with each other so that they do not loosen during operation.

5.The ambient temperature that can be used is -30°C to 50°C.

6.Avoid exposing the rubber parts to oil and sunlight.

7.Please contact us when using as an engine mount for construction machinery.

・Sliding wall

·engine

・Generator

・Electric motor

All rights reserved, © Copyright Kurashiki Kako Co., Ltd.

Feel free to contact us for a quote or inquiry